Bruker SkyScan micro-CT scanners come with Bruker’s 3D.SUITE software for image reconstruction, inspection, visualisation and analysis.

InstaRecon

World’s fastest micro-CT reconstruction software

- 10x – 100x faster than conventional CPU-based reconstruction.

- Uses patented algorithms for acceleration, instead of extra hardware (saving space and running costs).

- Available with all Bruker SkyScan instruments.

- Upgrades are possible for existing systems.

- Free one month demos available – contact us for details.

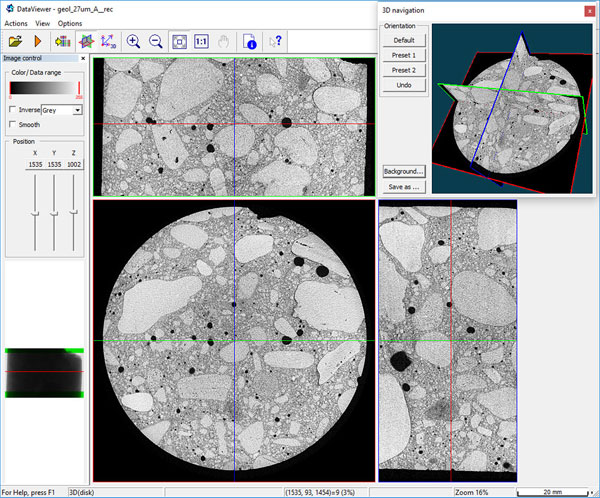

DATAVIEWER

3D inspection software

- View slice-by-slice movies and orthogonal projections.

- Process your images with smoothing, linear and non-linear grey scale transformations and colour coding.

- Differential image analysis between samples.

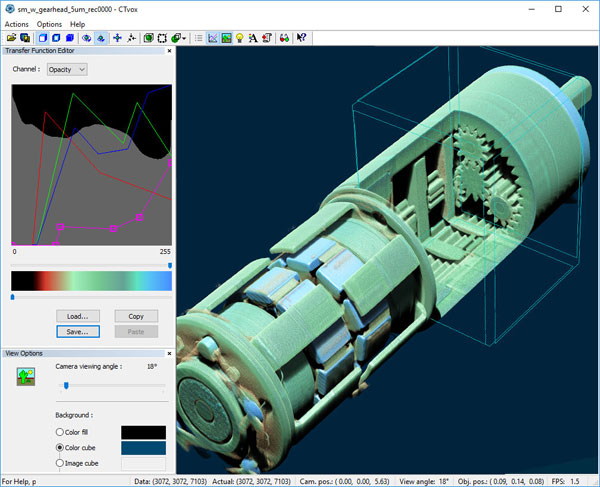

CTVOX and CTVOL

3D visualisation software

- Volume rendering – reconstruct your micro-CT data and view it as a realistic 3D object.

- Virtually fly around and through your sample and record movies.

- Render cut-away images.

- Edit colouring and transparency.

- Export surface rendered models in STL format for 3D printing, or other 3D CAD software.

- Compatible with mobile devices.

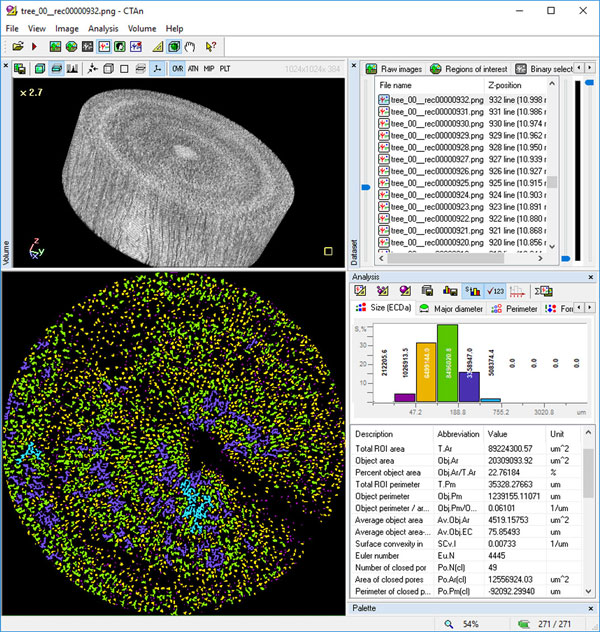

CTAN

3D image analysis software

- Density analysis

- Open/closed porosity

- 3D distances and angles

- Thickness and separation

- Select complex regions of interest

- Various thresholding methods, morphological operations and filter algorithms

- Colour code your sample by local orientation, thickness or separation

- Automated batch analysis

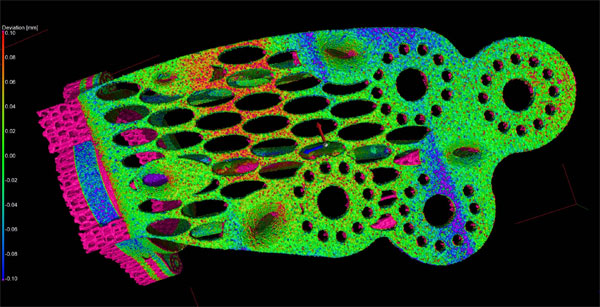

VGSTUDIO MAX

Alongside Bruker’s 3D.SUITE, data from SkyScan micro-CT scanners can also be processed with VGSTUDIO MAX, a software package from Volume Graphics for CT image visualisation and analysis of CT data. VGSTUDIO MAX is a high-end application with many useful capabilities:

- Measure difficult-to-access surfaces inside components

- Locate defects in castings, including pore cut prediction

- Defect analysis compliant with specifications P 201 and P 202

- Compare manufactured parts with CAD data, mesh data (.stl) and other voxel data

- Measure wall thickness and identify regions with an insufficient or excessive thickness or gap width

- Modular macros for automating processes

- Determine cell structures in porous foams and filter materials

- Calculate fibre orientation in composite materials – and other relevant parameters

- Virtual stress testing – non-destructively simulate mechanical stress from CT data

- Flow and diffusion experiments on porous materials, composites and more