Bruker Nanoforce

Nanomechanical Testing System

The Bruker NanoForce combines:

- Micro- and nano-mechanical testing

- Atomic Force Microscopy (AFM) imaging and nanoscale characterisation

NanoForce features advanced quasistatic and dynamic indentation technology, plus additional functionality unique to AFM. This combination delivers unprecedented ability from a single instrument: nanoscale precision together with detailed nanoscale property characterisation, along with the flexibility, ruggedness and reliability required for mechanical testing.

- Highly accurate results

- Ultra-low load capability, dynamic testing and AFM imaging

- Real-time control of all environmental variables during testing

- Flexible, all-inclusive test system – no extra add-ons or accessories to purchase

- Obtain data quickly and easily with user-friendly software

Blue Scientific is the exclusive distributor of the Bruker Nanoforce in the UK, Norway, Finland, Denmark and Sweden.

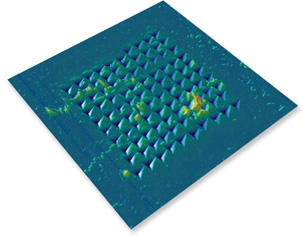

100 indents with Berkovich tip into steel; 1 μm grid spacing.

Flexible, All-Inclusive Mechanical Testing System

The Bruker NanoForce is an all-in-one nanoindentation solution. The system is designed so you can acquire useful data as straight away, without the need to add costly accessories after the initial purchase. All of these are included in the package as standard:

- Nanoindentation platform, stages and stage controllers

- Nanoindentation head and controller

- Microscope, including three optical objectives and 1000X NanoLens AFM

- Environmental and vibration isolation chamber

- All software, including dynamic testing

- Integrated vacuum stage

Dynamic Testing

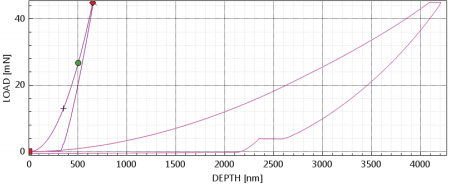

Nanoindentation systems usually measure materials by applying a constant load and measuring displacement. Dynamic nanoindentation involves a sinusoidal loading pattern, resulting in a wealth of useful material property data. Dynamic mode is included as a standard and is a key benefit the NanoForce.

Dynamic testing mode (standard on all NanoForce systems) enables

analysis of the phase shift. Above is the phase shift at a constant load over 10 seconds for elastic (Test 1) and viscoelastic (Test 2) materials.