Bruker TriboLab CMP

Small Scale CMP Polishing Process Control for R&D

The Bruker TriboLab CMP (Chemical Mechanical Processing) tribometer is specifically for cost-effective characterisation of wafer polishing processes in research and development

- Reproduce full-scale wafer polishing-process conditions

- Unmatched measurement repeatability and detail

- Test small coupons instead of whole wafers, for significant cost savings

Reduce Costs with Small Scale Testing

CMP process development and research into new materials and consumables (eg pads, slurries, conditioning disks) on full-scale production systems is expensive. The costs can add up: test wafers, consumables, overheads, depreciation and lost productivity when running tests instead of production wafers. With the TriboLab CMP you can perform studies on coupons cut from larger wafers, resulting in substantial cost savings.

Trusted Technology

Based on over 20 years of characterisation experience from its predecessor (CP-4) and the UMT TriboLab, the TriboLab CMP is the only process development tool providing a broad range of polishing pressures (0.05 – 50 psi), speeds (1 to 500 rpm), friction, acoustic emissions and surface temperature measurements for accurately characterising CMP processes and consumables.

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

Benchtop CMP Testing

Understand your Polishing Processes

- Greater visibility into transient polishing properties than any other instrument available

- Continuous data collection from the instant the substrate touches the pad, throughout the entire test

- Make early process development decisions based on complete, detailed data

Flexible Configurations

- Polish any flat material, using virtually any conditioning disc, slurry or pad

- Accommodates both small coupons and whole 100mm wafers

- Multiple sample mounts for versatility

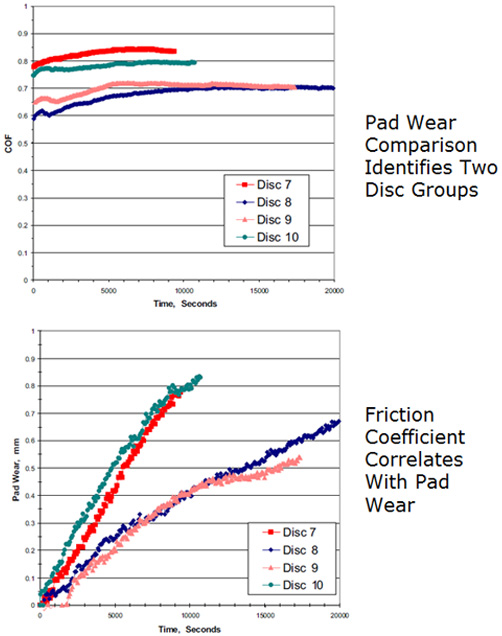

Testing Conditioning Discs: Tests identify two groups of discs. Friction coefficient tests correlate with pad wear.