Bruker UMT Tribolab

Versatile, Modular Tribometer

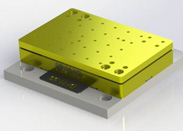

The Bruker UMT Tribolab (Universal Mechanical Tester) is a highly versatile tribometer, for testing mechanical and tribological properties.

Bruker’s UMT platform has become the most widely used tribometer on the market, since it was first released in 2000. Over the years it has been continually improved with powerful new features. Today’s model is modular for maximum versatility, offering greater functionality than ever before.

The UMT TriboLab is faster, with greater torque and more accurate force measurement than any other tribometer. TriboLab can perform all common tribological tests at the nano and micro scales. With a range of testing abilities and multiple possible configurations, it is used extensively in a range of industries including biomedical, microelectronics, paper and coatings, and throughout common industrial processes in petroleum, aerospace, automobile, engine, bearing and fastener manufacturing.

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

Applications

Surface degradation caused by friction, wear and corrosion have a detrimental and costly impact on machinery, manufactured products and production efficiency. Tribology is relevant in all industries, from mechanical, electromechanical, to chemical and even biological systems. Accurate friction and wear values are vital for parts and assemblies to function properly, as well as lowering costs and reducing waste.

Lubricant Testing

Versatile test configurations are possible to perform tests for compliance with industry standards, as well as custom tests requested by OEMs. With interchangeable modules, you can perform many different tests under varying environmental conditions. Performing standard and customised tests to accurately and efficiently characterise wear on parts and test the efficacy of lubricants.

High-Frequency Reciprocating Rig module for benchtop lubricant screening

Lab report: Characterisation of lubricants

Lab report: Tribology in automotive applications

Article: The relationship between sliding friction and surface texture

Thin Films and Coatings

While bulk material properties can be determined easily using common techniques, measuring the material properties of thin films in-situ requires more advanced analysis.

Perform a wide variety of mechanical tests on thin films and coatings. Indentation, scratch and reciprocating wear can all can be tested on a single platform using the Bruker UMT Tribolab. Perform extremely sensitive, detailed imaging of coatings using integrated atomic force microscopy or optical microscopy.

Glass Strength

By creating controlled defects in glass with known, controlled conditions, its strength and fracture resistance can be studied and improved. Research coatings, compositional modifications and microstructural and processing changes.

The Bruker UMT Tribolab can be fitted with a standard diamond tip (eg Rockwell indenter) to apply scratches of a precise and repeatable length and depth under servo-feedback controlled conditions. A three-point-bend fixture can then be used to fracture the glass under controlled conditions

Corrosion Testing

Understand the tribocorrosion process, including sliding wear, abrasion, cavitation damage, fretting, tribo-oxidation and solid particle erosion. This is relevant to a variety of applciations, including the automotive, biomedical, chemical, food processing, geothermal, marine, mining and petrochemical industries. Reduce loss of materials and improve product performance and reliability.

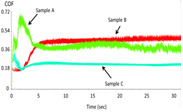

Measure friction force and normal force to obtain the coefficient of friction (COF) as a function of time. The tribocorrosion cell is equipped with a three-electrode, electrochemical measurement system, which calculates the removal rate of materials. The test system can also perform tests at high temperatures.

Low Friction Force Testing

Reducing friction between sliding interfaces is an area of increasing interest and research. In addition to assessing small differences in the performance of low-friction coatings and lower viscosity lubricants, testing the tribological performance of MEMS (micro-electro-mechanical systems) devices also requires measurement of extremely low friction forces, under similarly low normal forces.

Take extremely precise measurements using Bruker’s series of dual-axis force sensors. These feature an ultra-low noise floor of less than 0.02 mN and 500 mN capacity, and optional increased frequency response.

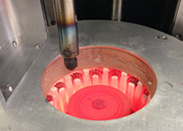

High Temperature Materials Testing

Test materials that need to maintain their strength at high temperatures – for example, metal for hot working, catalytic processing to remove harmful greenhouse gases and petrochemical processing. Test and compare materials from plastics to soft metals and super-alloys under high-temperature service conditions.

Various indenters are available with a range of force sensors, for a wide variety of material screening and comparison tests under conditions from room temperature up to 1000°C. Perform high temperature wear, hot rolling and hot hardness tests on a range of materials. All parameters can be set and controlled very precisely. Load can be controlled to microNewtons, sample temperature to +/- 1º centigrade, and position to within 1 micrometer. The flow rate of inert gas can also be controlled.

Stress-Strain Bend Testing

Elastic modulus in bending, stress-strain behaviour and failure limits in bending all can be studied via the simple sample geometry of a 3-point bend test.

In composite materials, failure can occur due to delamination between the fibers and the matrix, leading to complete specimen failure. The quality of materials can be tested easily using bend tests, and studying their ability to resist cracking or other surface irregularities during a continuous bend.

The Bruker UMT Tribolab can be equipped with an easy-to-use 3-point bend module, to test the properties of laminate and sheet materials. Tests can be run under load-displacement-control modes. An optional acoustic emission sensor (AE sensor) can be added to assess other composite research areas, including fibre surface activation, wetting chemistry of the matrix and fibre surface roughness characteristics.

Hard Metals and Facings

Testing hard metals and facings involves simulating the severe conditions of the application in service. The UMT TriboLab can apply high contact stresses and high sliding speeds with uni-directional or reciprocating motions, while monitoring temperature, friction and wear. It can also be set to automatically terminate the test when pre-defined conditions are met. This versatility means that virtually any kind of hard metal or hard facing can be tested under application-specific conditions.

Example applications include:

- Gate valves in high pressure systems

- Drill and cutting tool bits and inserts

- Mining and road construction

- Plain bearings for stationary power generation

Test key parameters specific to your application, including the coefficient of friction during start-up, galling resistance under low speed high stress sliding and resistance to high temperatures generated by high sliding speeds.

Technical Details

Most tribology instrumentscan perform only one single test, and do not offer the versatile modularity of the UMT TriboLab. Transform the platform from rotary to reciprocating motion in minutes, or from sub-newton to kilonewton force measurement, or turn the temperature up to 1000°C for environmental testing.

The key element in the TriboLab’s design is a high performance motor mounted in the centre of a vibration-dampened column. This motor accommodates a full range of speeds and torques. Four interchangeable mechanical drives turn this power into linear and rotary motion, for all types of rotary, reciprocating, block-on-ring and linear tribology and scratch-test configurations.

Configure the TriboLab to meet your specific testing needs:

- Versatile modular drives

- Choice of high-load, high-performance sensors

- Accessories to modify the temperature and environment