EX-300 Shallow Probe

LEXES-based semiconductor compositional metrology system

The CAMECA EX-300 Shallow Probe is a front-end semiconductor compositional metrology system for 22nm node and beyond. It’s installed at top-ten semiconductor fabrication facilities worldwide.

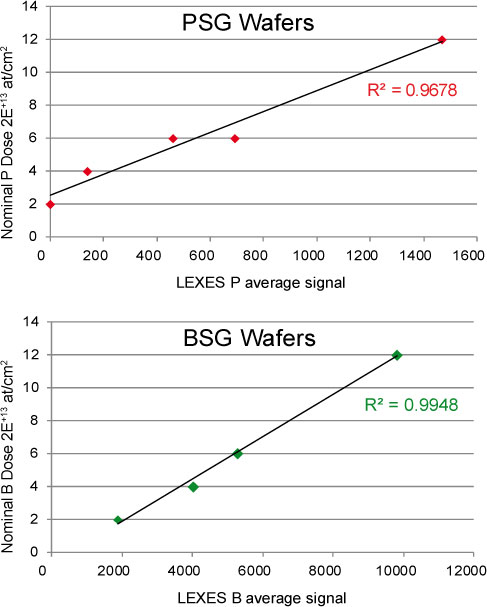

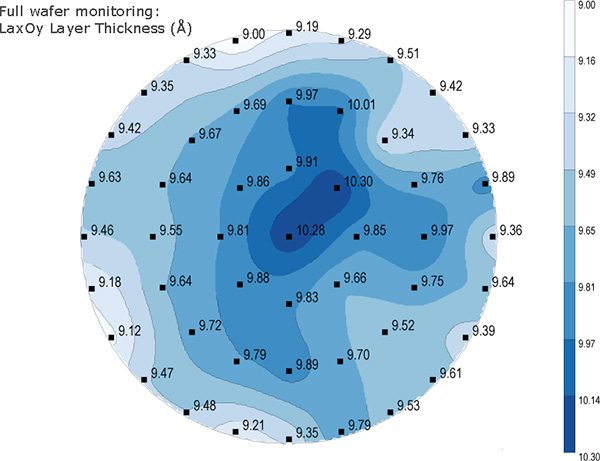

The EX-300 uses LEXES (Low energy Electron induced X-ray Emission Spectrometry) technology to measure chemical composition at the surface and near surface. A single system controls both composition and thickness, all kinds of stacks (mono or bi-layer, with/without capping) as well as production and blanket wafers.

- Ultra shallow implants – Monitor low energy, high concentration implants.

- Strained silicon process control – Measure chemical composition and thickness of epitaxial layers (eg B:SiGe and P:SiC) with no limits on layer composition.

- HKMG metrology – Control both the oxides and metal with a single EX-300.

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

Features

- Robust, flexible pattern recognition

- Optimised light source & optics

- Zooming capabilities

- Small pad analysis (30×30μm)

- Non-contact

- Non-destructive

- High brightness LaB6 gun

- Dense, highly focussed probe

- Optimised MTTR (mean time to recovery)

- Ergonomic design for fast maintenance

- Ultimate long-term stability

- Optimised pumping system

- Define parameters to monitor automatically

Accelerate Time-to-Market

Bring logic and memory devices to market sooner:

- Control your front-end processes: HKMG, SiGe(B), SiC(P), implants.

- Select key process parameters during device development.

- Shorter ramping phase to enter mass production faster.

Save Money

Increase yield in high volume production:

- Catch process excursions with early measurement on wafer products.

- Save weeks of production output.

- Reduce product loss.