IntraSpect 90

Nanoindentation system for Raman microscopes

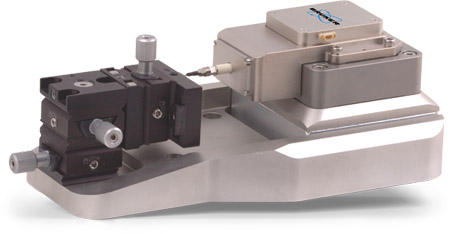

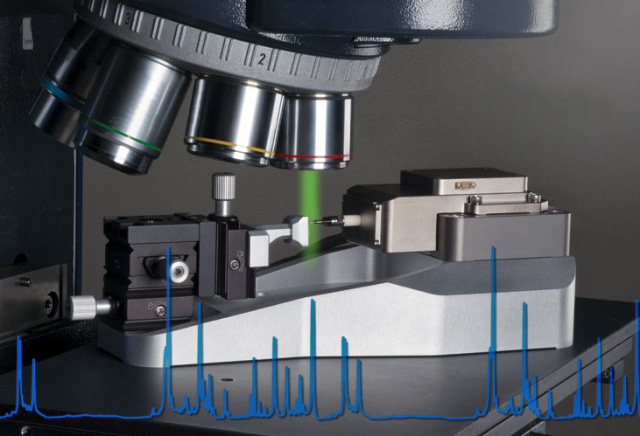

The Bruker Hysitron IntraSpect 90 is an in-situ nanoindentation system that integrates with existing Raman microscopes. Add it to your microscope for simultaneous Raman characterisation during small-scale indentation, tension, compression or bend testing.

Contact us for more information and quotes:

+44 (0)1223 422 269 or info@blue-scientific.com

Details

Mechanical Testing on Your Raman Microscope

The Bruker Hysitron IntraSpect 90 mounts easily on the stage of an existing optical or Raman microscope. It’s a compact system with an extended sample mount, so the objective lens can access the deformation zone easily. With locking sample stages you can position samples easily, with minimal sample shift during testing.

Understand Deformation Processes

Bruker’s unique transducer design provides up to 500 mN of force and 150 μm of displacement with unsurpassed noise floors. Take advantage of truly quantitative nano- to micro-scale mechanical testing with simultaneous Raman observation. Mechanical data can also be synchronised to the real-time optical imaging for a more complete understanding of the evolution of deformation.

Testing Modes

Indentation

Using a 3-axis positioning stage, the sample is positioned beneath a pyramid-shaped diamond probe. The Raman laser source focuses directly on the contact zone at an angle of 90°. This enables you to observation pressure-induced phase transformations, amorphisation and molecular re-arrangement beneath the contact point.

Tensile Testing

With a unique micro Push-to-Pull (PTP) device, you can apply uniaxial tension forces to small-scale fibres, films and 2D materials – all with simultaneous Raman spectroscopy. Stress and strain values can be obtained easily from the raw force and displacement data, correlating with structural changes.

Compression Testing

Stress is applied to micro-scale pillars, particles and other small scale structures using a flattened diamond probe. Observe the micro-structural origins of deformation behaviour and strength – particularly useful when developing advanced engineered materials.

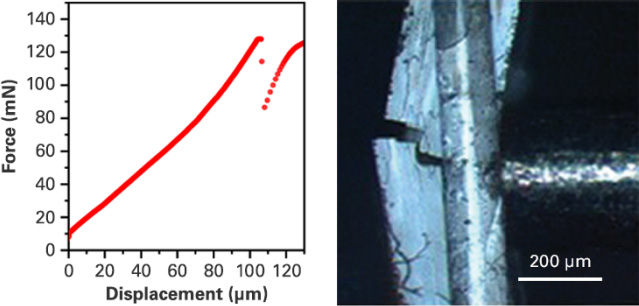

Bend Testing

Measure the elastic and fracture properties of micro-cantilevered and clamped beam specimens. With simultaneous optical imaging, you can observe fracture initiation and propagation through the sample.

Gallery

Synchronised mechanical data and imaging during a bending test on a crystalline sample. Mechanical phenomena such as fractures can be captured and analysed easily with a full picture of what’s happening.