TI 980 TriboIndenter

Hysitron’s most advanced nanomechanical and nanotribological testing system

The Hysitron TI 980 TriboIndenter delivers maximum performance, flexibility and speed. Gain a comprehensive understanding of material behaviour at the nanoscale. The TI 980’s base configuration features:

- Quantitative nanoscale-to-microscale indentation

- Nanoscratch

- Nanowear

- High resolution in situ SPM imaging

- Dynamic nanoindentation

- High speed mechanical property mapping

Quantitatively characterise materials to the low end of the nanoscale. The system is configurable to test over 6 orders of magnitude in force and 10 orders of magnitude in displacement, for almost any material in any form.

Futureproof System

To meet your changing requirements in future, the TI 980 is an extremely flexible system, supporting the largest range of hybrid and correlative nanomechanical characterisation techniques.

- Universal sample mounting options:

- Mechanical

- Magnetic

- Vacuum

- Modular environmental enclosure, with integrated access ports for future expansion

- Versatile software for instrument control and data analysis

Synchronised Multiscale Measurements

- Seamless measurement with multiple transducers, each perfectly optimised for the measurement at hand.

- Powerful base configuration includes nano-to-micro indentation, nanoscratch, nanowear, high-resolution in-situ SPM imaging, dynamic nanoindentation and high-speed property mapping

Versatile Software

For system control:

- XPM™ ultra-fast nanoindentation

- SPM+ in-situ SPM imaging

- Dynamic surface finding

- Enhanced sample navigation

- Automated instrument calibration

- Automated test routines

For data analysis:

- Powerful data processing and analysis

- Tribo iQ™ graphing software

- Programmable data analysis modules

- Automatic, customisable reports

Automation

- Automated calibration for perfect results:

- Tip-area function calibration

- Transducer calibration

- Tip-to-optics offset calibration

- Automated test routines:

- High-throughput, fast multi-sample testing

- Validate the probe shape at specified intervals

- High-resolution multiscale imaging; Survey the whole sample optically for a simpler workflow

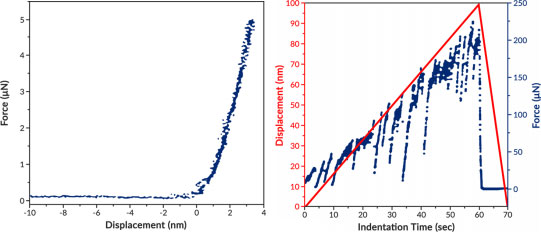

Low Noise Floor

- Quantitative characterisation from the microscale to the very bottom of the nanoscale

- Nano-newton force noise

- Displacement measurement capabilities smaller than the diameter of 90% of atoms

- Force and displacement noise floors are guaranteed at your facility at installation

Fast Feedback Control

- Maximum accuracy, reliability and repeatability

- Force and displacement feedback control algorithms developed specifically for the physics of Hysitron transducers

- Full sense-analyse-control loop every 0.000013 seconds, for fast measurement and response to transient events

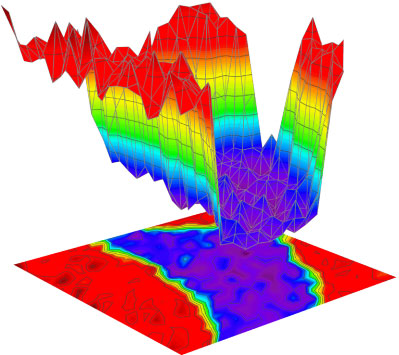

XPM property mapping: Collect more data in an afternoon than could be collected in an entire year using traditional nanoindentation methodologies.