Hand-picked scientific laboratory instrumentation for battery research and testing.

Not sure which technology is best for your lab? Contact us for independent advice

Battery and Fuel Cell Research

- Characterise high power cells and batteries – more than a battery cycler: Ametek SI-9300R Battery Analyser

- Small battery, supercapacitor and micro fuel cell characterisation – Solartron Modulab XM ECS (Electrochemical Test System)

- High quality impedance measurement and battery materials testing eg membranes, separator materials etc – Solartron potentiostats

- Cost-effective potentiostat for battery research – Princeton Applied Research VersaSTAT series and PARSTAT 4000A

- Higher current device impedance testing, and ohmic drop ESR equivalent series resistance measurements and for GSM/CDMA pulse measurements – Solartron Modulab XM ECS (Electrochemical Test System)

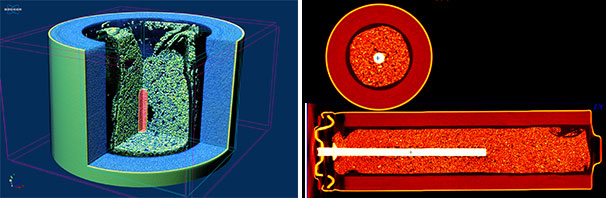

- Non-destructive internal imaging – Bruker microCT

- Multi channel battery and cell test equipment in conjunction with EIS – Maccor – Contact us for more information

- Monolayer weight change analysis – Quartz Crystal Microbalance

- Battery research with AFM

Non-destructive internal imaging with micro-CT

Nanomechanical Testing

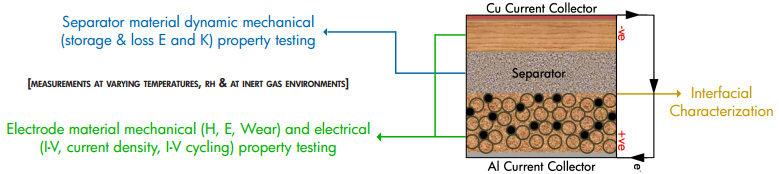

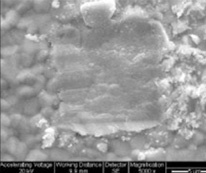

The stability in charge-discharge rates with increasing number of electrochemical cycles dictate the lifetime of a battery. To improve the lifetime, the relationship between the battery degradation mechanism and the mechanical properties of the electrode and separator coatings has been explored. It has also been understood that the degradation rate is not only dependent on the electrochemical reactions, but also on the mechanical stability and properties of the coatings and materials respectively. To achieve the goal of significantly improving the efficiency, one other approach could be processing optimisation of various battery components and further mechanical characterisation at different degrees of electrochemical cycles. Nanomechanical testing is an established characterisation technique with proven versatility and much needed sensitivity for process optimisation in the battery industry, both in R&D andmanufacturing.

Testing quantitative nanoscale mechanical and electrical properties:

- Hardness measurement – Nanoindentation – all Hysitron instruments

- Delamination or film failure testing – NanoScratch – TI 950 – optional on TI Premier

- Young’s modulus measurement – Nanoindentation – all Hysitron instruments

- Quantitative wear resistance testing – ScanningWear – Hysitron TriboScope and TI 950

- Surface morphology and roughness measurement – In-situ SPM imaging – TI 950, TI Premier, (Triboscope using existing AFM scanner)

- Quantitative adhesion characterisation – Nanoindentation and NanoScratch – TI 950 – optional on TI Premier

- Dynamic modulus and stiffness – storage and loss – nanoDMA and modulus mapping – optional with Hysitron instruments

- Nanoscale electrical conductivity (I-V) measurements, current density mapping and I-V cycling – nanoECR – optional with TI 950 and TI Premier

Nanomechanical Characterisation Techniques for Battery Component Materials