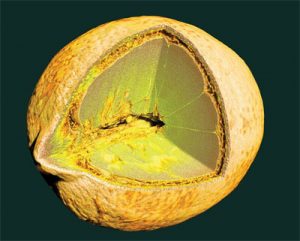

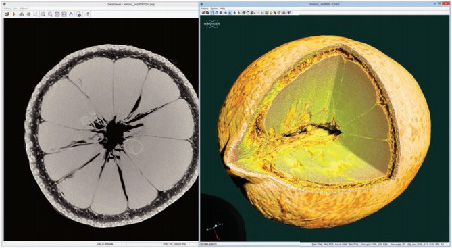

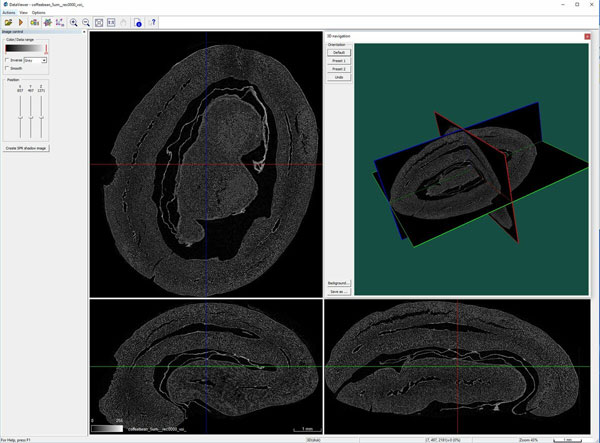

X-ray micro-computed tomography (μCT) is a non-destructive technique for studying internal micro-structure in 3D – with sub-micron resolution. It’s also known as X-Ray Microscopy (XRM).

In the food industry, you can investigate the relationship between structure and properties in product development, as well as gaining insights into shelf life, etc. Analyse samples of any shape, including delicate foods, with little to no sample preparation.

See how micro-structure relates to food properties

Applications

Micro-CT can be used to measure and investigate these and much more:

Food Industry Areas

- New product development

- Reformulation trials

- Food product changes over time

- Shelf life determination

- Packaging (including defects)

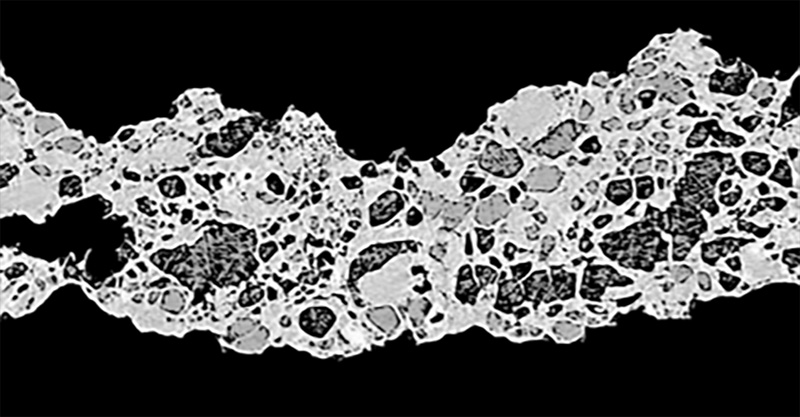

Porosity

- Porosity/ density

- Bubble size and distribution

- Fine walls in bakery products

Structure and Texture

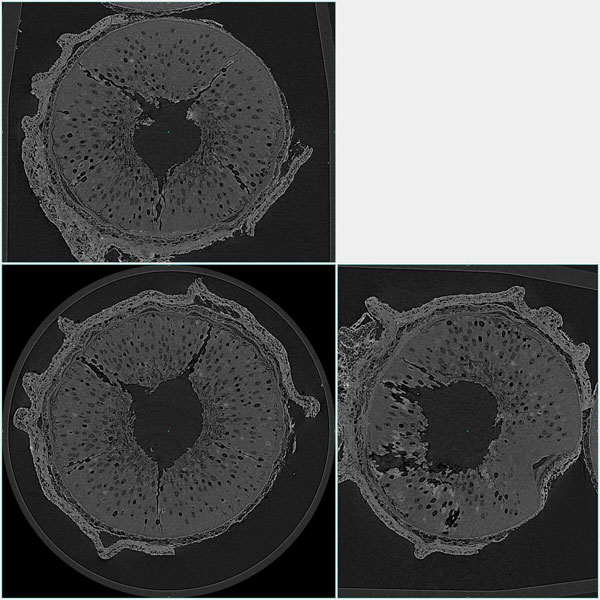

- Structural characterisation

- Texture

- Effects of processing

- Effects of ingredients and additives on structure

- Expansion and cracks – with sub-micron resolution

- Distribution of particles

- Moisture migration

- …and more

How Campden BRI use Micro-CT

Stress-Testing Seeds

Europe’s news network Euronews featured how micro-CT is used to analyse how seeds respond to stress tests, in order to select seeds that produce the maximum yield.

Bruker XRM Instruments

Blue Scientific is the official distributor of Bruker XRM in the UK, Norway, Denmark, Sweden, Finland, Iceland and Norway. Just get in touch if you’d like any more information or advice and we’ll be happy to help.

Bruker SkyScan 1275

Fast, self-optimising benchtop XRM scanner. High quality scans at the press of a button.

Bruker SkyScan 1272

Sub-micron resolution from a benchtop X-Ray Microscopy system. World’s first scanner with >200Mp in each cross-section.

Bruker SkyScan 2214

Multi-scale nano-CT for the widest range of object sizes/ resolutions.