Metals Analysis with OES (Optical Emission Spectrometry)

How to analyse metals for process and quality control with OES (Optical Emission Spectroscopy) using the Bruker Q8 MAGELLAN. The system offers unlimited combinations of parameters for measuring:

- Homogeneity

- Cleanliness

- Oxygen content

- …and more

Blue Scientific is the official Nordic distributor for Bruker OES instruments in the Nordic region (Norway, Sweden, Denmark, Finland, Iceland). For more information or quotes, please get in touch.

Bruker X-Ray & Elemental Analysis Instruments

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Follow @blue_scientificWhat Can You Measure?

OES is an element analysis technique that allows unlimited combinations of parameters for measuring:

- Iron and steel alloys and traces

- Nitrogen in steel

- Aluminum alloys and traces

- Copper alloys and traces

- Oxygen in copper

- Nickel alloys and traces

- Cobalt alloys and traces

- Magnesium alloys and traces

- Tin alloys and traces

- Lead alloys and traces

- Titanium alloys and traces

Optical Emission Spectrometry (OES)

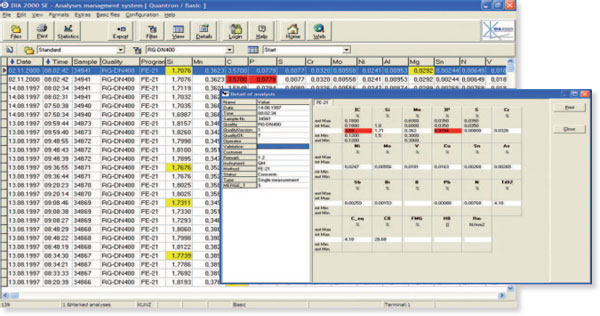

The Bruker Q8 MAGELLAN spark spectrometer statistically evaluates time-resolved measurements of the individual spark. It uses new algorithms for to determine dissolved/undissolved element portions and detect non-metallic inclusions. This enables precise measurement of oxygen content, oxide and sulfide inclusions, and particle size distribution of various oxide and sulfide types (including aluminum oxide, calcium aluminate and magnesium aluminate spinels).

Cleanliness Determination and Inclusion Analysis

Homogeneity and cleanliness are extremely important quality parameters in steel production. Premium steel products in particular demand high degrees of cleanliness and low oxygen levels.

SEM-EDX is the traditional method for determining non-metallic inclusions, using a metallographic microscope and scanning electron microscope with EDX. However this is a slow and costly technique. OES with pulse discrimination analysis (OES-PDA) can determine cleanliness and oxygen levels more quickly and efficiently. The process can be controlled in real time, by measuring quality indicators during the melting process.

Final Product Checks

OES can also be used to check final products. Bruker’s MCI (Metal Cleanliness Inspection) software was designed for this exact purpose. Sparks caused by non-metallic inclusions are statistically evaluated to determine:

- Total oxygen content

- Oxide and sulfide inclusions

- Grain size distribution of various oxide and sulfide types (eg alumina, Ca-aluminate and Mg-spinel)

Samples with a Copper Matrix

For samples with a copper matrix, you can analyse the elemental composition of pure copper with impurities of only a few ppm, with low detection limits of detection and tight tolerances.

Purity of Incoming Materials

With OES you can also check the purity of incoming materials to verify delivery quality, assess suppliers and reject substandard materials. By accurately measuring material grades and purity, you can optimise your margins and identify defective materials that could potentially cause problems or halt the complete production line.

The traditional method for evaluating purity was by using a microscope (SEM-EDX). However this method is costly, time consuming and provides only partial sample reviews. In contrast, the Bruker Q8 MAGELLAN OES system takes only a few seconds to deliver information about purity levels, oxygen content and chemical composition. Sample preparation is very simple, making the entire process quick and easy to perform.

Bruker Q8 MAGELLAN

The Bruker Q8 MAGELLAN is high-end OES / spark spectrometer tailored to the particular requirements of metal analysis during the manufacturing process. It’s also suitable for the demanding steel and aluminium industry and high-tech metals in aerospace and automotives.

- Fast and accurate

- Unlimited combinations of measurement parameters

- Low detection limits

- One-button operation and simple sample preparation

- Calibrated to internationally certified standards (each instrument is sparked individually at the factory)

- Low running costs – Argon flow is switched off during standby, reducing gas consumption

- Long-term stability and cleaning cycles

More Information

Blue Scientific is the official Nordic distributor of Bruker OES instruments. We’re available to answer all your questions – just get in touch: