Micro-Diffraction vs Standard Powder XRD in Geology

The standard method for XRD in geology is wide area powder scanning with Bragg-Brentano geometry. An alternative method is XRD microanalysis, which enables you to scan smaller spots in-situ, without grinding the rock. This reveals information that can be missed by bulk scanning.

Blue Scientific is the official Nordic distributor for Bruker XRD in the Nordic region (Denmark, Norway, Sweden, Finland, Iceland). For more information or quotes, please get in touch.

Bruker D8 Advance

Posts about geology

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Follow @blue_scientificAdvantages of XRD Microanalysis

XRD (X-Ray Diffraction) is often used in geology for qualitative and quantitative mineralogy.

Usually, in bulk mineralogy, the sample is ground to a homogenous powder and analysed with divergent beam geometry (Bragg-Brentano). With microanalysis, the sample can be analysed in its native state without grinding. This is ideal for certain situations:

- Analyse rare samples

- Characterise individual constituents

- Investigate the spatial relationship of multiple phases within an assemblage

Trace mineral phases are revealed that can’t be identified with traditional powder methods alone. This is possible by rotating the sample in a pseudo-Gandolfi mode (phi rotation and psi oscillation).

Example: In-Situ Lazulite Crystal

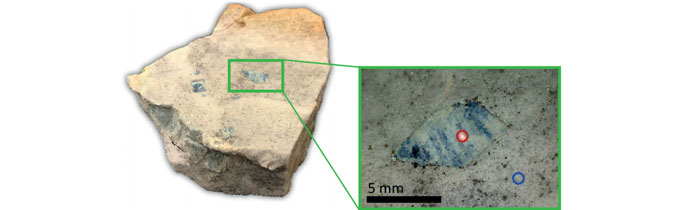

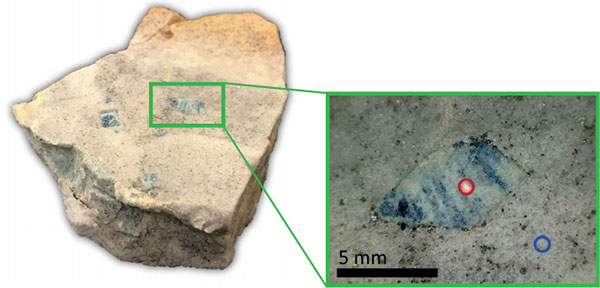

In this example, an in-situ lazulite crystal and its surrounding matrix were analysed using both methods to compare the results:

- Large area Bragg-Brentano with 1D detection

- Small area micro-diffraction (µXRD) with 2D detection

The lazulite sample is from the Carolina Slate Belt in Georgia, where low- to medium-grade meta-volcanics were mined for kyanite for high-alumina refractory products. This area is also renowned among mineral collectors for high quality twinned rutile crystals, iridescent hematite coatings on quartz, lazulite, pyrite and pyrophyllite.

This example is available to download in an application note from Bruker.

Instrumentation

Measurements were performed using the Bruker D8 ADVANCE diffractometer, equipped with:

- Copper (Cu) radiation

- TRIO multipath optic

- Compact CradlePlus

- EIGER2 R 500K detector

With the EIGER2 detector, you can switch easily between 1D and 2D geometry. This means you can collect both traditional powder scans and micro-diffraction data.

More about the EIGER2 detector…

Method 1: Bragg-Brentano

Bragg-Brentano geometry is traditionally used for mineralogical specimens. A wide area scan was collected from the green box in the image above using a line beam and scanning 1D detector mode. The specimen was rotated in phi during the measurement.

The diffraction pattern is dominated by quartz from the matrix (shown below). Trace amounts of variscite and pyrite were also identified. However, the phases associated with lazulite are absent, despite visual confirmation.

Bragg-Brentano works well for powders, but fine details can become lost in noise or even missed completely, like in this example.

Method 2: Micro-diffraction

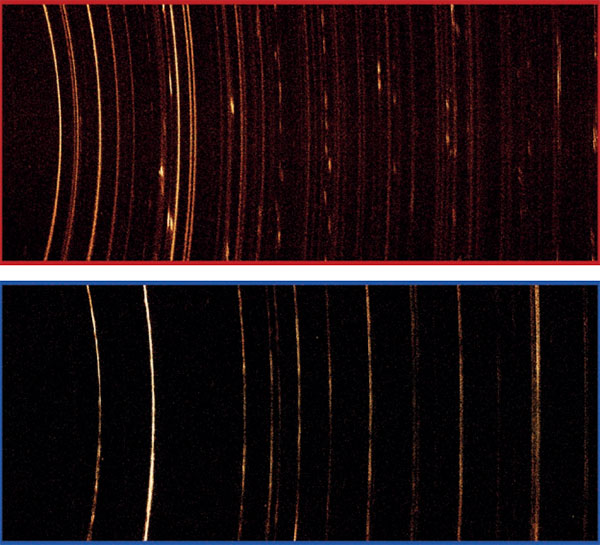

In the 2D measurement, the lazulite crystal and quartzite matrix were measured in-situ using a 0.5 mm spot beam and the EIGER2 in scanning 2D mode. During the measurement the specimen was rotated in phi at 3 rpm and oscillated in psi from 0˚ to 35˚ (pseudo-Gandolfi) to provide more reflections.

Micro-diffraction confirms that the matrix is primarily fine-grained quartz. Data from the large lazulite crystal shows intergrowths of polycrystalline variscite, metavariscite and gypsum.

Bruker D8 Advance

With EIGER2 detector

- Switch easily between 1D and 2D geometries, for traditional powder scans and microdiffraction

- Automatic optimisation for acquiring high quality data easily

- Flexible, modular system

- Maintenance-free goniometer

- Lifetime alignment guarantee

Any Questions?

Blue Scientific is the official distributor of Bruker XRD. We’re available to answer all your questions – just get in touch: