XRD in Battery Development

An overview of how XRD (X-Ray Diffraction) is used in battery development and energy storage materials analysis.

X-Ray Powder Diffraction in Battery Materials Development

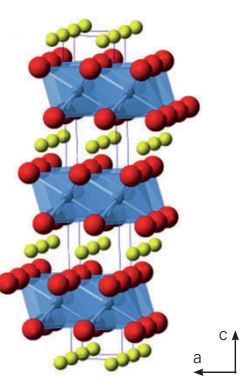

X-ray powder diffraction is ideal for studying the structure of new battery materials, which are usually produced in powder form.

The lattice parameters and details of their crystal structure of active compounds can be determined with Rietveld refinements, as well as data about the crystallite size which is related to their reactivity.

In-situ XRD

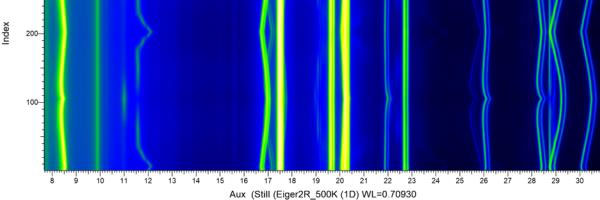

The phase diagram of batteries can be mapped using in-situ XRD, with respect to their charge state, and to correlate the different phases with the voltage profile.

Specialist battery cells are available for in-situ XRD that enable investigation of the cathode or anode without dismantling the cell. Compared to ex-situ measurement, this avoids relaxation of meta-stable phases as well as degradation and contamination of active materials. In-situ measurements are also much faster for creating phase diagrams, as multiple charge states can be investigated using the same sample.

In-Operando XRD/Electrochemistry

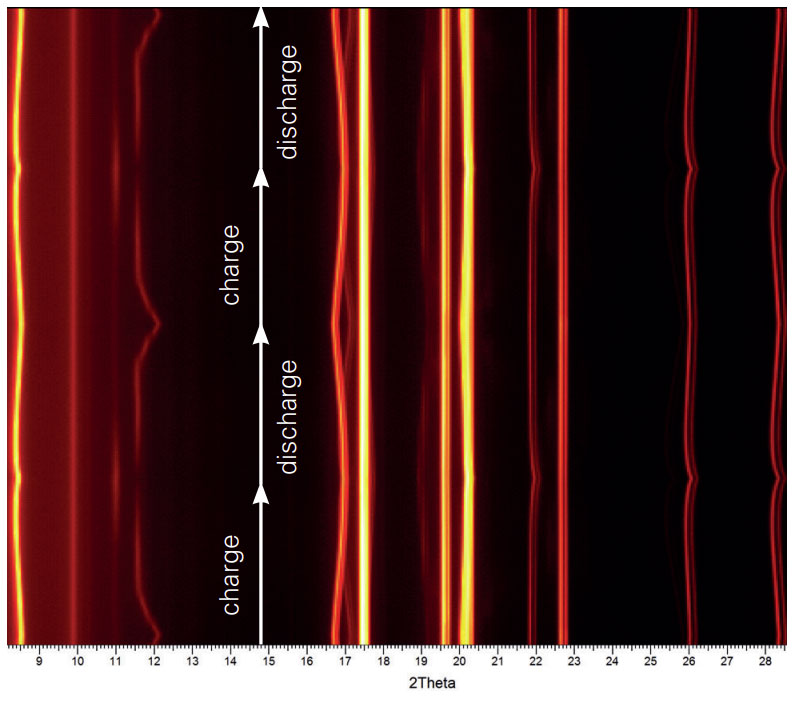

The reaction mechanism of the intercalation of Li-ions in the active compound is important in battery research. Electrochemical processes can be studied live by connecting the battery cell to a potentiostat, which controls the charge-discharge of the cell during the experiment.

Both the changing phase composition and the evolution of the crystal structure can be tracked simultaneously. This provides insights into energy storage materials at an atomic level. You can follow the reactions that take place during cycling and monitor degradation behaviour, to improve battery performance.

With in-operando experiments you can track the emergence of new phases at various charge states and determine whether a reaction occurs as an intercalation in a solid-solution (single-phase) or with multiple intermediated phases.

In-operando XRD/electrochemistry can also be used to quickly identify critical voltage limits for phase-transitions, which can negatively affect the cell’s capacity.

Example: In Operando XRD of Battery Pouch Cells

In this lab report from Bruker, see how in operando XRD was used to study an NMC pouch cell using the Bruker D8 ADVANCE equipped with the EIGER2 R 500K detector.

Battery Workshop (Online)

Bruker is hosting a free, online battery workshop on Thursday 7th October 2021 at 2:30-5:30pm CEST. The workshop will showcase XRD and XRM (X-Ray Microscopy) characterisation techniques for optimising the physical and chemical properties of battery components.

The event will include insights into battery development with in-situ XRD at the LRCS Energy Hub in France, live XRD demonstrations and opportunities to ask questions with Bruker specialists.

Bruker D8 ADVANCE

- Flexible system for XRD, PDF (Pair Distibution Function) analysis and SAXS / WAXS.

- Market-leading accuracy for peak positions, intensities and resolution.

- All sample types: liquids, loose powders, thin films and solid blocks.

- Change instrument configuration without tools or alignment.

- Range of models, including the ECO with low energy consumption and no external water cooling.

More Information

Blue Scientific is the official distributor of Bruker XRD systems in the Nordic region (Finland, Norway, Sweden, Denmark and Iceland). We’re available to provide quotes, demonstrations and answer all your questions – just get in touch: