Working Towards Climate-Neutral Steel Production with OES Metals Analysis

As the steel industry works to reduce its carbon footprint, aiming for climate neutral production, elemental analysis is required to ensure product quality is maintained. OES (Optical Emission Spectrometry) is a useful metals analysis technique to monitor concentrations of vital elements at all stages of production and recycling, as processors work to reduce emissions without compromising quality or steel grades.

Blue Scientific is the official Nordic distributor for Bruker OES instruments in Norway, Sweden, Denmark, Finland and Iceland. For more information or quotes, please get in touch.

More about metals analysis

Bruker Q4 Tasman

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Climate-Neutral Steel Production

Steel manufacturers face challenges to achieve goals of net-zero emissions by 2050, and the possibilities of making steel with hydrogen instead of coal and carbon capture strategies. There are also challenges in processing scrap steel and re-introducing it into the production process, with higher levels of recycling needed to increase the efficiency of the industry. While working towards these goals to reduce CO2 emissions, it’s also vital to maintain quality and not compromise steel grades.

Elemental Analysis

Elemental analysis is important for helping metal manufacturers achieve climate goals and maintain product quality. Bruker’s metal analysers and OES (Optical Emission Spectrometry) systems, such as the new Q4 TASMAN Series 2 are ideal for this task. OES is a flexible technique, and a reliable workhorse for all metal analysis tasks.

What is OES?

Optical Emission Spectrometry is a very fast analytical method for metals. It covers chemical elements from sub-ppm to percentage levels, from pure metals trace analysis to high alloyed grades. All relevant elements are analysed simultaneously.

It’s speed, ease-of-use and versatility make it a preferable choice. It’s also a robust system, so it can operate at all stages of metal production and processing for material inspection, alloy identification and quality control.

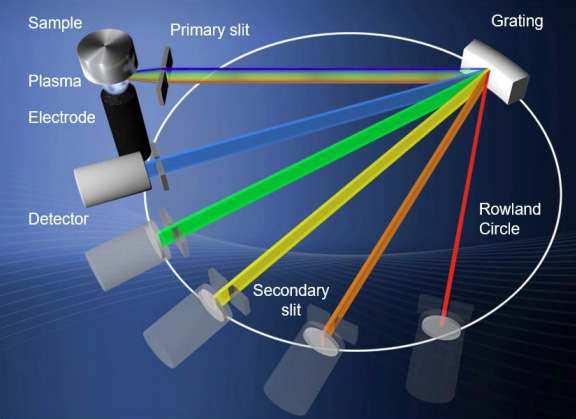

How does it work?

Emitted light is guided into the optical system and dispersed by a diffraction grating. Detectors at specific positions quantify the emitted light. The intensity of each specific line correlates directly with the abundance (concentration) of the element in the sample.

Bruker Q4 TASMAN Series 2

- Flexible for all metal analysis tasks.

- Compact and rugged, for the lab or melt shop floor.

- Results in less than a minute.

- Easy sample preparation.

- Low cost of ownership.

- Low maintenance, with self-cleaning spark stand, long-lasting electrode and argon stop function.

Analysing Steel with OES

The Q4 Tasman is rugged and compact, and suitable for use either in the lab or on the melt shop floor. It has integrated air conditioning, so hot or humid environments are not a problem.

The chemical composition of the steel can be determined and monitored at various stages of the refining process. Samples are taken from the liquid steel. They’re prepared by grinding or milling (eg with Al-corundum paper, ~60 grit) for a flat, homogeneous surface.

Analytical solution packages are available for all 10 common metal bases. Each package includes:

- Analytical programs optimised for each alloy group

- Calibrations

- Source parameters

- Full set of elements

This table shows the typical measurement time for analytical programmes for various metals:

| Metal | Typical Measurement Time |

|---|---|

| Low alloy steel | 25 seconds |

| Free cutting steel | 56 seconds |

| Cast iron | 29 seconds |

| Fe – Cr/Ni Steel (stainless steel) | 25 seconds |

| High speed steel | 25 seconds |

| Mn-steel | 25 seconds |

| Ni-resist / Cr-hard steel | 28 seconds |

Calibration ranges for each package and results demonstrating the reproducibility of the Q4 Tasman for low, medium and high carbon, low alloy steels are available in an application note from Bruker.

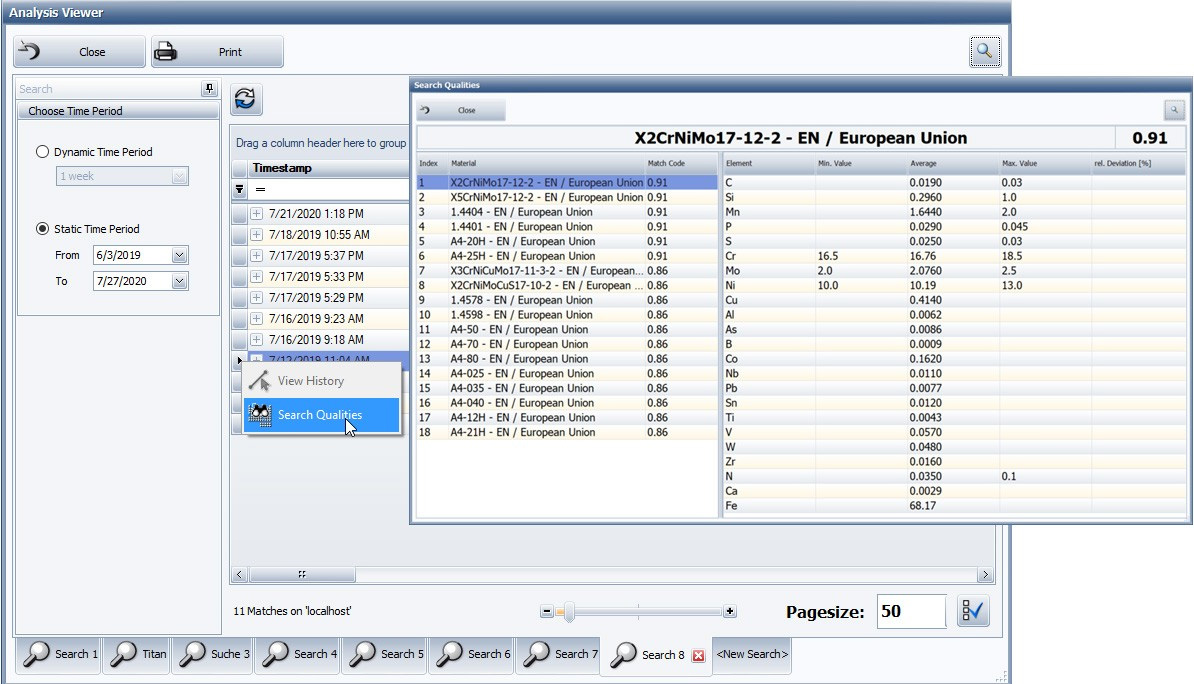

Total Materia

Total Materia is the most comprehensive database in the world for metal properties and cross-referencing. It integrates information from 74 Standard Development Organisations, hundreds of producers and other sources. All this data is easily accessible via a superfast search engine.

Combined with Bruker OES analysers, Total Materia is the ideal tool for:

- Scrap sorting.

- Positive material identification.

- Grade determination.

- Checking is metals are within the specification.

- Find equivalents to foreign materials and compare alternatives side by side .

- Search worldwide materials by chemical composition or mechanical properties.

- Decipher material specifications and find the correct grade for each application.

More about metals analysis with Total Materia…

More Information

Blue Scientific is the official distributor of Bruker OES systems in the Nordic region. We’re available to answer all your questions – just get in touch: