Characterising CMP Pads with Nanoindentation

How to use dynamic nanoindentation characterise CMP pads. In this example, the Bruker Hysitron TS 77 Select was employed to quantitatively measure the viscoelastic properties of a hard pad.

This is a robust, reliable method for examining CMP pad surface quality and processes.

CMP in Microelectronics

Chemical mechanical polishing (CMP) is used in microelectronics for interlayer dielectrics and metal layer planarisation. Pads are a key consumable used for polishing in the CMP process. The mechanical properties of the pad and its surface morphology affect the quality and effectiveness of polishing.

Metrology Techniques

Metrology techniques such as dynamic mechanical analysis and Shores hardness characterisation are commonly used to measure and understand the mechanical and viscoelastic properties of CMP pads. However, there are limitations to these techniques. They provide non-localised, average values of hardness and modulus for large volumes of the sample, including the pores, which are often not adequate for quality control.

Nanoindentation for Smaller Scale Measurement

Nanoindentation, in contrast, measures properties quantitatively at smaller scales. There’s a high degree of control over test parameters such as:

- Indenter loading / unloading rates

- Dynamic oscillation

- Peak load

- …and more.

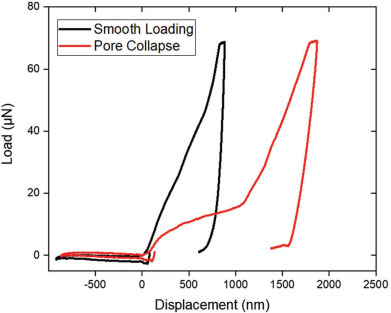

The results are not affected by pores in the pad surface, because of the small contact area, precise targeting ability and surface stiffness mapping.

Example: 100 MPa “Hard Pad”

This example involves measuring the near surface properties of a commercial CMP pad; a 100 MPa “hard pad”. It uses the Bruker’s Hysitron TS 77 Select, a benchtop system for automated nanomechanical testing.

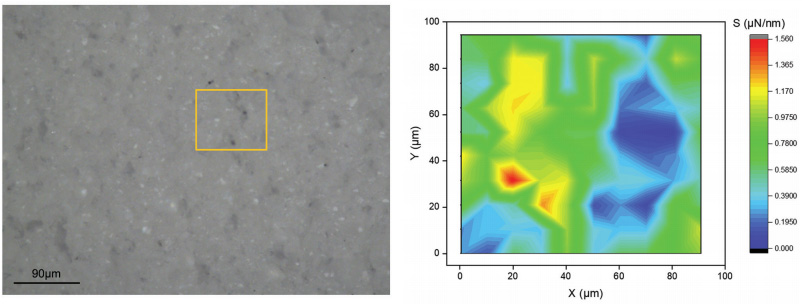

Dynamic indentation was used to measure properties including storage modulus, loss modulus and tan delta as a function of depth. Large grids of indents were made using the TS 77 Select’s automated features. Statistics were then calculated and maps were generated of regions containing pores.

Full details of the experiment are available in an application note from Bruker.

Right: Contour map of stiffness from the 10×10 area.

Viscolelastic Properties

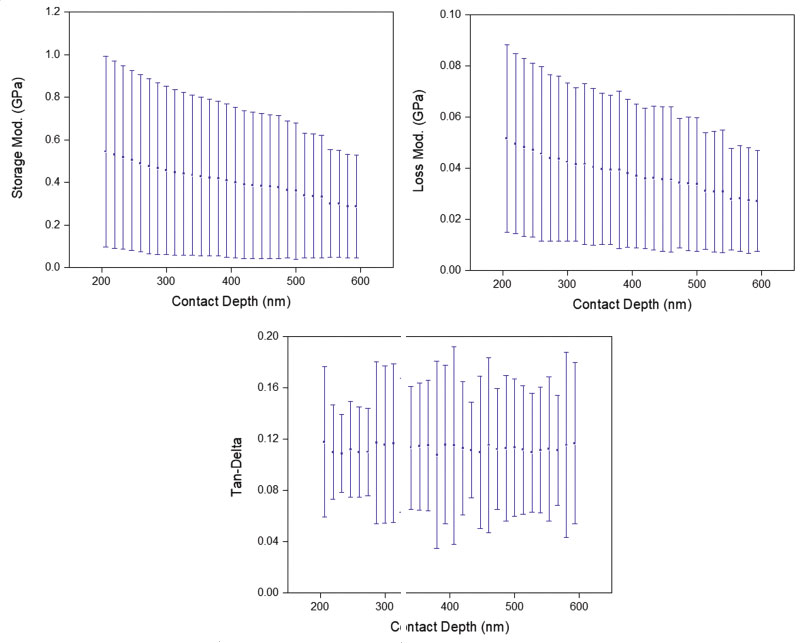

The graphs below show the viscoelastic properties of the hard pad, including storage modulus, loss modulus and tan delta between 200 and 600 nm of contact depth.

Histograms

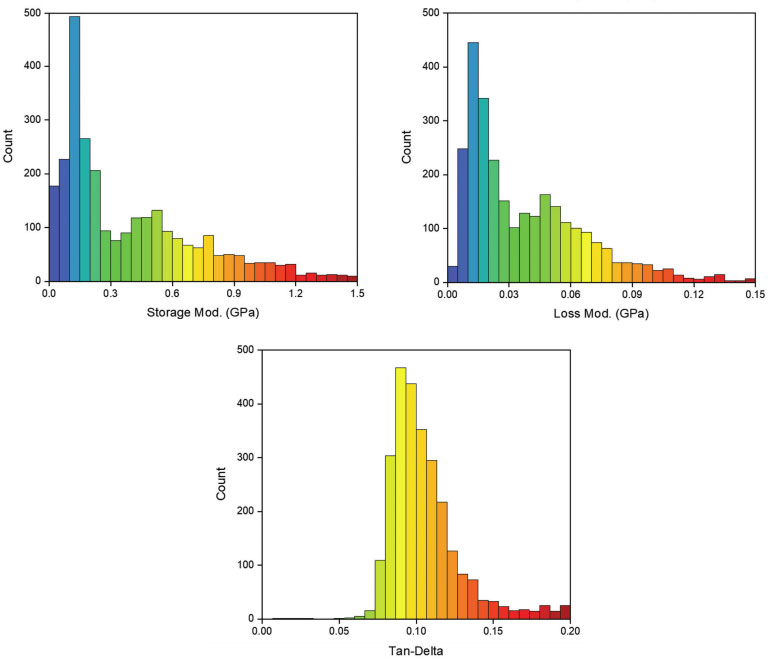

The histograms below depict the storage modulus, loss modulus and tan delta for the hard pad, for contact depths 200 to 600 nm.

Conclusion

This method can be used to quantitatively measure various properties of CMP pads, including cross-sections, to gain a better understanding of pad surface quality and processes.

The set-up allows full control over the indenter loading and unloading rates, peak load and other test parameters.

Constant Strain Rate dynamic indentation tests on the top surface of the pad delivered depth profiles of storage modulus, loss modulus and tan delta.

By indenting away from pores and using a large number of indents, there appears to be a structural variation in the pad that produces a bimodal distribution of modulus.

Bruker Hysitron TS77 Select

- Best-in-class, entry-level nanoindenter.

- Quantitative mechanical / tribological characterisation at the nanoscale to microscale.

- Essential toolkit of testing modes.

- Automated routines for reliable characterisation.

- Based on established Bruker technology.

More Information

BlueScientific is the official distributor of Bruker Hysitron systems in the Nordic region (Sweden, Denmark, Finland, Norway and Iceland). We’re available to answer all your questions – just get in touch: