Analysing Coating Thickness with Micro-XRF

Measure coating thickness with Micro-XRF. Analyse single and multiple layers and coatings quickly and accurately, using the Bruker M4 TORNADO. In this example, light elements were measured in a vacuum.

Blue Scientific is the official distributor for Bruker Micro-XRF in the UK, Ireland and Nordic region (Finland, Norway, Sweden, Iceland and Denmark). For more information and quotes, please get in touch:

Bruker M4 TORNADO

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Analysing Coating Thickness and Layers

Micro-XRF spectrometry is ideal for analysing thin layers and coatings:

- Non-destructive – Micro-XRF will not damage your sample.

- Analyse below the surface – X-rays penetrate the material, to analyse layers below the surface.

- Single or multiple layers – Measure coatings, thin layers or multi-layer materials.

Example: Analysing Thin Layers in a Vacuum

In this example, thin layers are measured in a vacuum. Both the aluminium layer and the silicon substrate are light elements. If they are not measured under vacuum, the air in the beam path between sample and detector would absorb the low energy radiation emitted by the sample.

This case study also compares compares manual and automated analysis.

Instrumentation

The instrument used in this example is the Bruker M4 TORNADO, a versatile micro-XRF spectrometer.

- Suitable for all sample types

- High spatial resolution

- Fast data processing

- High speed, motorised XYZ-stage for sample positioning

For this example, the M4 TORNADO used a large vacuum sample chamber and a focused X-ray beam (spot size < 20 µm) to induce fluorescence in the sample. This signal is analysed with an energy dispersive detector.

Measurement Conditions

The X-ray tube settings used for the analysis were 50 kV and 200 µA. Samples were measured at a pressure of 20 mbar. 15 measurements were taken on each sample. The acquisition time for the manual measurements was 60 seconds. Automated measurements were taken using Bruker’s Auto-Point software, with a point number of 20 and point distance of 70 µm. Acquisition time for the automated measurements was shortened to 10 seconds per point.

Results

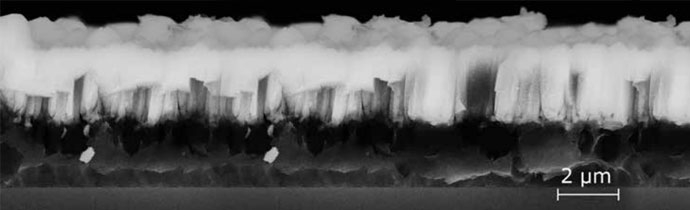

The measurement results are shown in the table below, for both manual and automated measurements.

Manual vs automated coating thickness measurement results, obtained with micro-XRF.

The thickness of the layers is around 2 µm. It is difficult to compare the manual and the automated results, because of the different measurement locations, but both show that the sample 2 is thicker than sample 1. The comparable standard deviations show that, even though the automated measurements had a shorter acquisition time, it still provides reliable results.

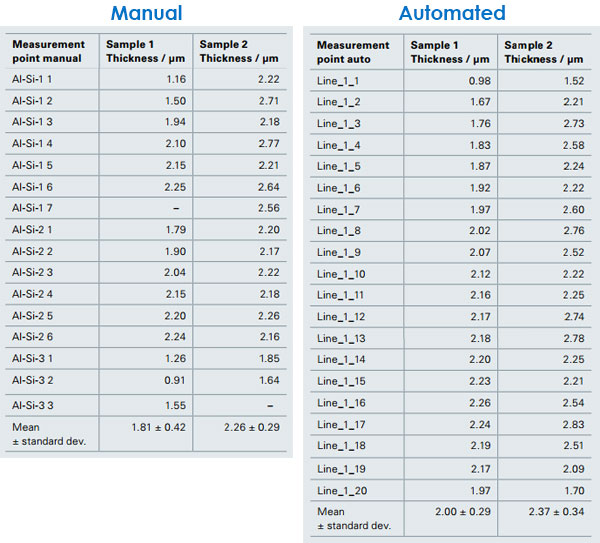

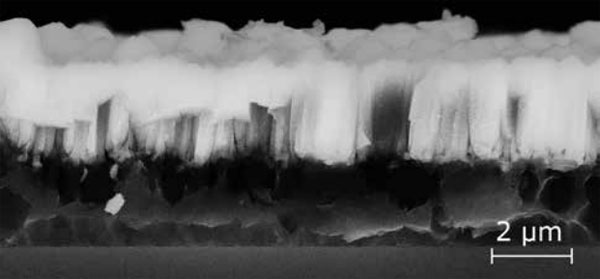

To verify the results, the sample was measured using a scanning electron microscope. The image below shows a fractured edge:

SEM image of the layer structure.

Conclusion

This example demonstrates how Micro-XRF can be used to measure the thickness of layers and coatings at specific locations. The method is fast, accurate and non-destructive. Light elements in layers and substrate can also be measured using the vacuum option.

Further Information

For more information about analysing coating thickness and layers, please get in touch:

Bruker M4 TORNADO

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com