Studying Foam with Micro-CT (3D X-Ray Imaging)

Techniques and instrumentation for studying foam with micro-CT (X-ray µCT):

- Analyse the internal structure in 3D

- Realistic visualisations

- Map morphometric parameters

- In-situ stages for dynamic mechanical testing

Blue Scientific is the official distributor for Bruker Micro-CT in the Nordic region (Norway, Sweden, Denmark, Finland, Iceland). For more information or quotes, please get in touch.

Micro-CT Systems

More posts about Micro-CT

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

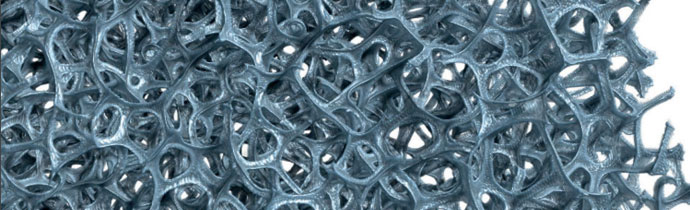

Micro-CT: 3D Internal Imaging

A key benefit of micro-CT is it’s non-destructive nature. You can image the internal structure of your material in 3D, without damaging or affecting the sample. The volume is reconstructed virtually on your PC, with all internal details presented at high resolution. Take virtual slices and even flights through the sample, and examine the structure at any location you choose, along different planes.

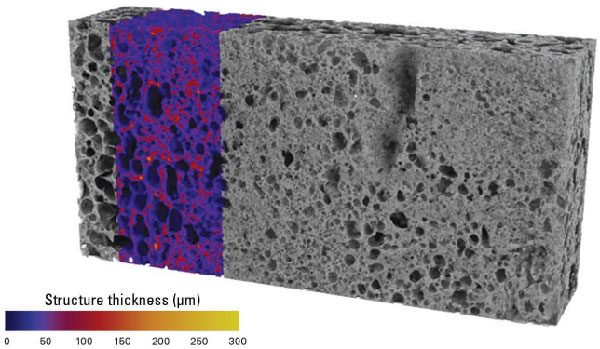

Structural Analysis

With image processing tools in the software, you can study the foam’s internal morphometry, including:

- Porosity

- Average thickness

- Thickness distribution

Structural thickness or separation is measured by placing a virtual sphere in every space with a maximum diameter that fills the sphere. This information on local 3D morphometric parameters is then used to create a visual map showing the distribution of spatial intensities.

Colour-coded 3D thickness map of aluminium foam. Taken with the Bruker SkyScan 1272 (5 µm voxel size).

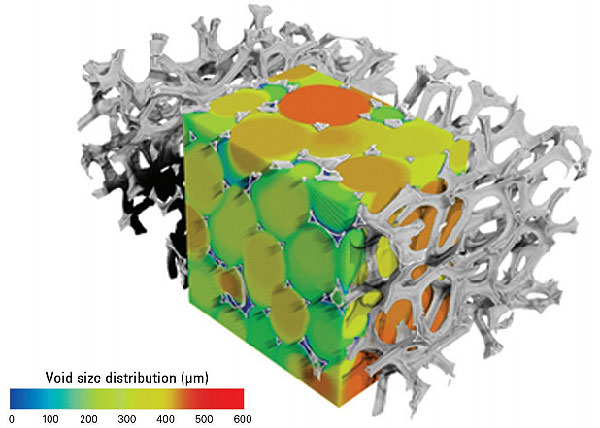

Reconstructions and Data Mapping

Once the sample has been scanned, realistic models are generated for visualisation and you can take virtual flights through the material. These can be exported as videos, showing the view around and inside the foam.

As well as realistic models, you can also create maps (like the one above) to display morphometric data, with colour coding to illustrate the local distribution of data. These are highly visual, adding impact to presentations of your results, as well as making it easier to visualise and understand your data.

These maps can include multiple datasets if required. For example, the image below shows the reconstruction of the foam together with colour-coded structure separation, to highlight pore network size distribution.

Multi-volume image of open-cell nickel foam showing both the reconstruction and a colour-coded structure separation map. This displays the diameter of the foam cells, as well as the hollow struts. Taken with the Bruker SkyScan 1272 (1 µm voxel size).

In-Situ Testing

You can perform dynamic mechanical experiments inside the scanner, with specially designed in-situ stages:

- Compression testing

- Tensile testing

- Temperature variation

This enables you to study correlation between the foam’s structure and mechanical properties.

The example below is an in-situ compression test of open-cell aluminium foam, using Bruker’s Material Testing Stage and a 440 N load cell. Controlled compression was applied to the both ends of the foam. Throughout the test, the loading curve is displayed on screen in real time.

Stages are available for mechanical testing up to 4.4 kN. In-situ temperature control is available from 40°C below ambient, to +85°C.

Volume rendering of foam at different compression points. The colour-coded structure separation data shows you the effects of compression at each point. Taken with the Bruker SkyScan 1275 (15 µm voxel size).

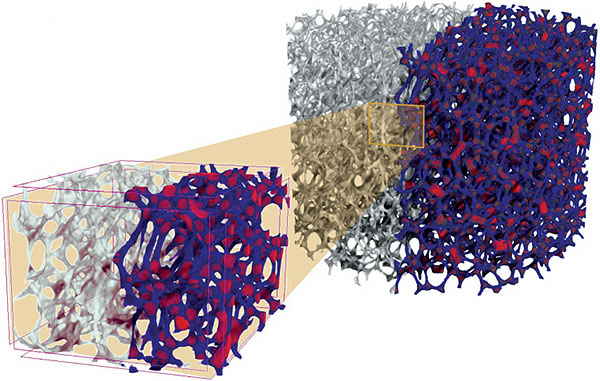

Fast Scans & Automation

Data can be acquired in less than 1 minute. Even at this speed, a huge amount of detailed structural information is acquired, as shown in the example below (scanned in just 57 seconds).

With automated micro-CT, parameters are optimised automatically so you can scan at the press of a single button. These routines include the full workflow of scanning, reconstruction and analysis. This means that micro-CT can be used quickly and easily by non-specialists – for example in quality control.

Scan of aluminium foam, taken in just 57 seconds. Red = foam nodes; Blue = connections. Taken with the Bruker SkyScan 1275 (30 µm voxel size).

Instrumentation

Bruker SkyScan 1272

High resolution benchtop micro-CT:

- 11 or 16 Mpx large area CCD camera

- Down to 0.35 µm pixel size

- Up to 200 Mpx in every slice

- InstaRecon: the world’s fastest reconstruction algorithm

- 16 position sample changer

Bruker SkyScan 1275

Self-optimising automated micro-CT:

- Down to 4 µm pixel size

- Automated, push-button routines

- Sample size up to: 96mm diameter x 200mm high

- Licensed exact spiral reconstruction

- 16 position sample changer

In-Situ Stages

- Compression up to 4400 N

- Tensile up to 440 N

- Cooling down to 40°C below ambient

- Heating up to 85°C

Further Information

Blue Scientific is the official UK and Nordic distributor for Bruker Micro-CT. If you have any questions or if you’d like a quote, please get in touch.

This post is based on information from a brochure from Bruker; Please get in touch if you’d like a pdf copy.