Failure Analysis of Metals with SEM / EDS

Combined SEM and EDS gives you morphological characterisation and compositional information together, making it easier to correlate results and draw conclusions. Here are several examples of how SEM/EDS can be used in failure analysis of metals: in bend tests, coating defects and corrosion in the automotive industry.

Blue Scientific is the official distributor of the Thermo Scientific Axia ChemiSEM SEM/EDS system in the UK and Ireland. For more information or quotes, please get in touch.

SEM / EDS Instruments

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Combined SEM and EDS

By combining SEM and EDS data you can study morphological characterisation and compositional information together, making it easier to correlate results and draw conclusions, which can be extremely useful in failure analysis.

The Thermo Scentific Axia ChemiSEM combines SEM with EDS simultaneously. Quantitative information from EDS is accessible at any time while imaging.

Data from both techniques is acquired continuously, making it twice as fast as other SEM/EDS systems. These are then displayed together for a better understanding of the elemental distribution.

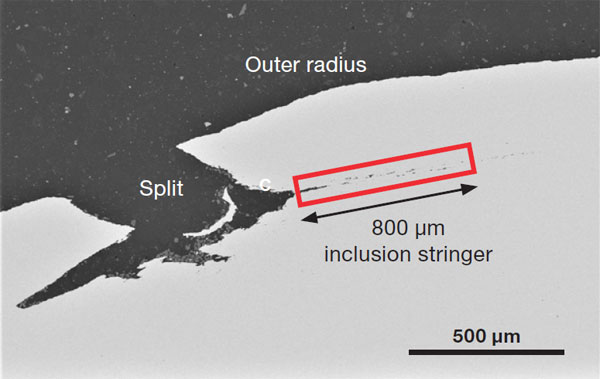

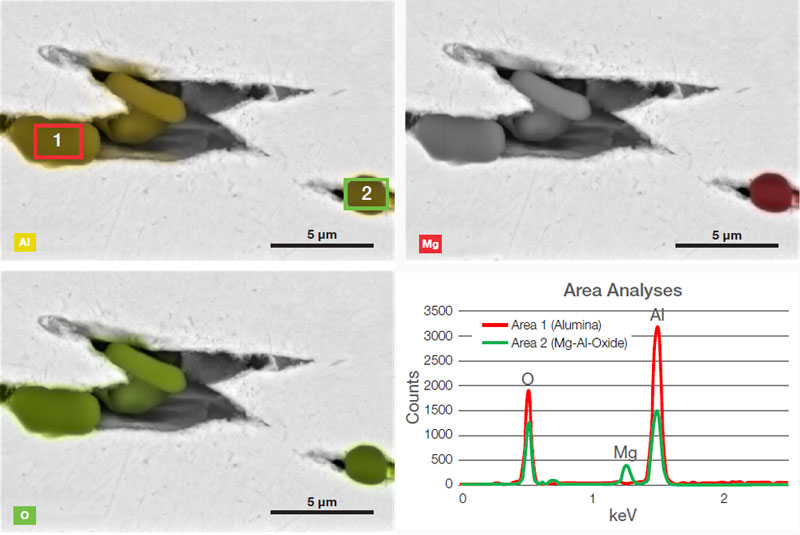

Bend Failure Analysis in Steel

Bend testing is commonly used to test the ductility of steel and other materials, and to check their resistance to fracture. When fractures or cracks occur, SEM and EDS can be used to characterise the failure and quickly determine its root cause.

In the example below, HSLA (High Strength, Low-Alloy) steel failed a bend test. Using the Axia ChemiSEM to view a cross-section, the split was examined and a stringer was located. EDS provided compositional information about inclusions in the stringer. It could then be determined that a cluster of non-metallic inclusions had spread out into a linear defect during the hot rolling process, which caused the failure in the bend test.

More information is available in an application note, including details about the examination and results. Contact us for a copy.

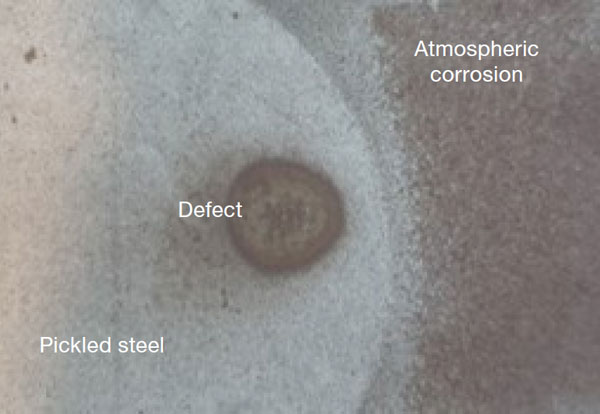

Corrosion Failure Analysis

Pickling is a steel surface treatment, used to create a uniform surface without stains, and to remove oxides after hot rolling processes. The process uses an acid solution, which is then washed off.

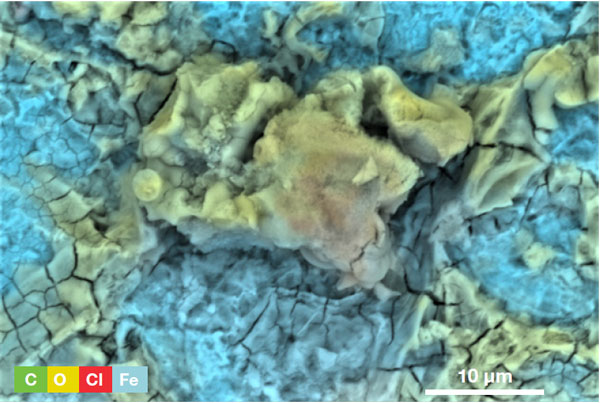

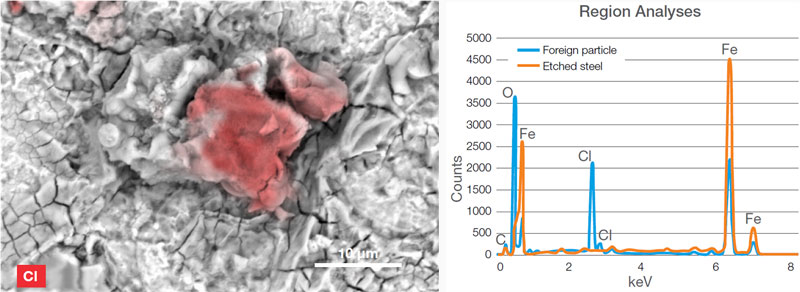

In this example, stains were found on structural steel after pickling, and SEM/EDS was used to identify the root cause of the contamination.

The Axia ChemiSEM was used to examine the surface morphology and chemical constituents of the defect. In about a minute a map was created, displaying microscopic surface features colour-coded to show their composition. This showed that the surface stain was rich in chlorides and had a higher oxygen content, suggesting that a drop of hydrochloric acid contacted the surface after cleaning.

Full details about the examination and further images are available in an application note; please contact us for a copy.

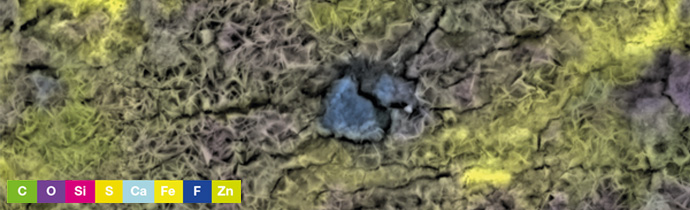

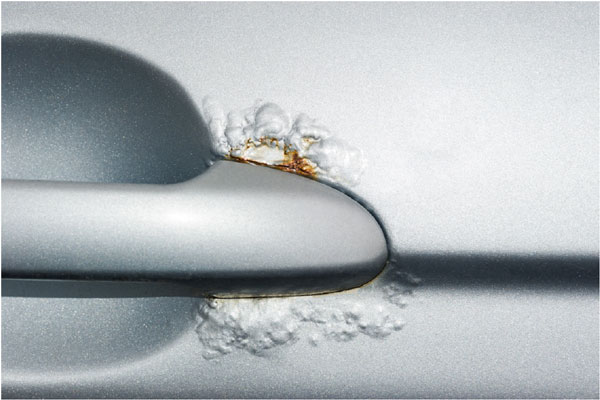

Coating Defects on Automotive Parts

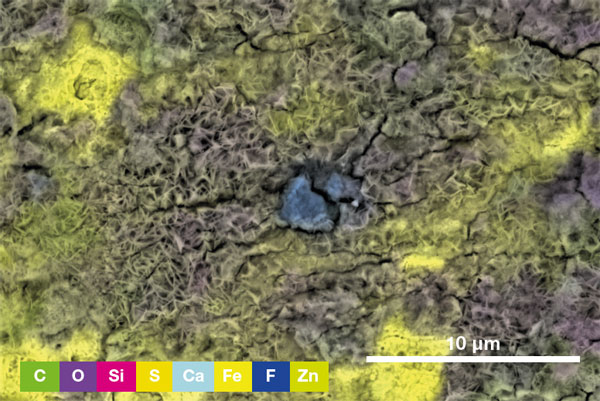

SEM/EDS can be used to examine defects in layers of protective coatings, to understand the root cause of the defect and prevent it in the future. This is useful for example in the automotive industry when producing exposed steel panels (eg doors and roofs) with coatings for resistance to atmospheric corrosion.

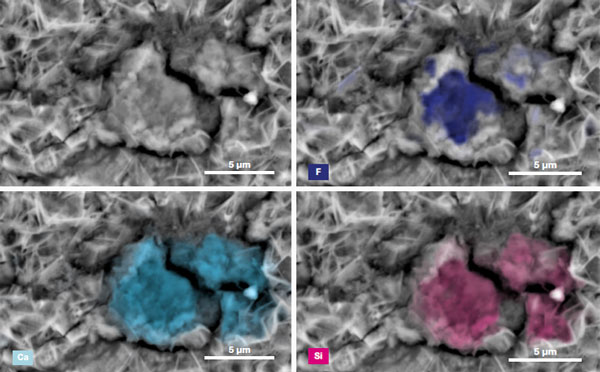

In this example, the Axia ChemiSEM was used to investigate the presence of foreign particles and quickly assess their composition. Unlike traditional SEMs, the ChemiSEM provides instant access to elemental information for accurate failure analysis and defect discovery.

The study identified a foreign particle, with elements suggesting mold powder residue. Mold powder is used for heat control, lubrication and to prevent oxidation. This prevented the protected coating from adhering to the steel, leading to corrosion.

Further details about this investigation and how it was carried out are available in an application note; contact us for a copy.

Thermo Scientific Axia ChemiSEM

- SEM with live EDS quantitative elemental mapping.

- Accessible and easy to use, with automated features.

- View quantitative elemental information at any time.

- Large, flexible chamber.

- Acquire data twice as fast as other SEM-EDS systems.

More Information

Blue Scientific is the official distributor of the Thermo Scientific Axia ChemiSEM in the UK and Ireland. We’re available to answer all your questions – just get in touch: