Integrating SEM and EDS in one system makes it much quicker and easier to identify the root cause of failures. It’s up to twice as fast as conventional techniques, for a lower cost-per-sample and long-term savings.

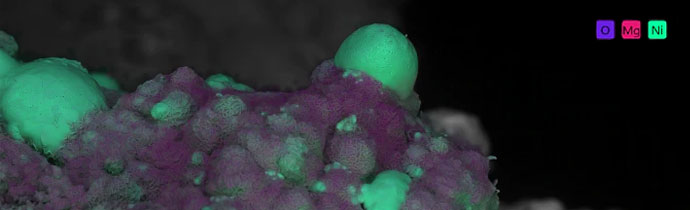

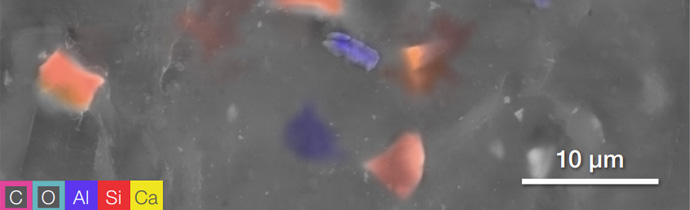

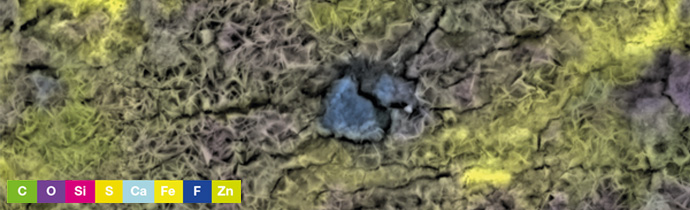

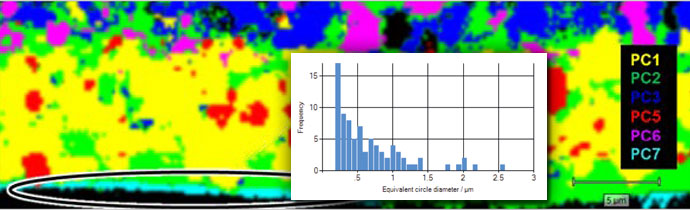

SEM-EDS can be used to characterise the composition of polymer composites. This is useful in failure analysis, to detect and identify contaminants and defects, and to check homogeneity.

How SEM/EDS is used in failure analysis of steel, with examples of bend test failures, coating defects and corrosion in the automotive industry.

We’re proud to announce a new partnership with Thermo Fisher Scientific as official distributor of the Axia ChemiSEM scanning electron microscope in the UK and Ireland.

How to analyse layers and coatings with Raman spectroscopy, with the example of paint on coated metal.

Unambiguously identify organic contamination on silicon wafers and micro-electronics with a AFM-IR technique, using the Bruker Anasys nanoIR3.

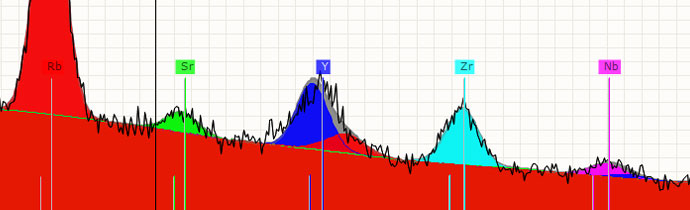

Analytical techniques for process control of manufacturing involving metal powders. How XRD, XRF and micro-CT are used for failure analysis, element composition and mapping, crystalline phase identification, parts inspection and more.

Join Bruker for a webinar about different approaches to bulk quantification with micro-XRF, for those working in failure analysis, quality control, materials, metals and R&D.

Discover more about in-situ SEM (Scanning Electron Microscope) nanomechanical testing with a personal in-situ SEM nanoindentation demonstration. The demos will be held at the University of Birmingham on 28 and 29 May, after the MidSEM (Midlands SEM) meeting. Contact us to book your session now. Personal In-Situ SEM Nanoindentation Demonstrations Pairing the high sensitivity of nanomechanical testing with the high […]