For quantitative elemental information at any time

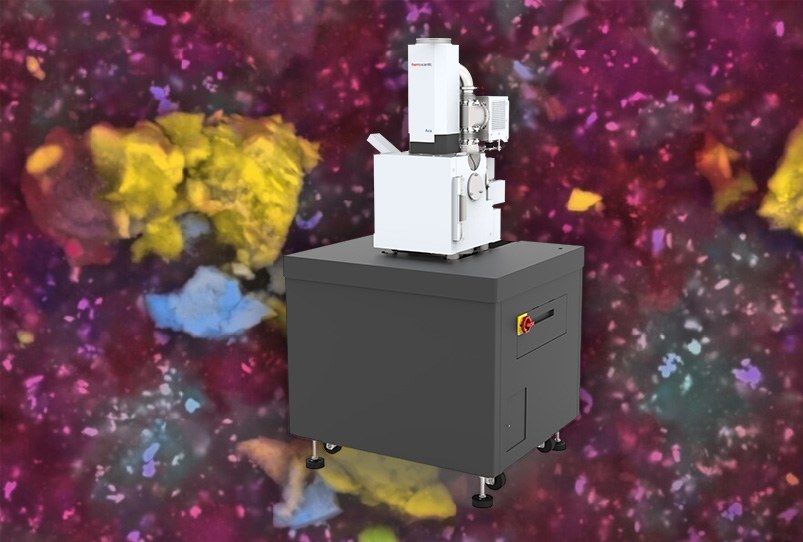

The Axia ChemiSEM is designed to make SEM more accessible and easier to use, with convenient automated features and live EDS elemental mapping.

Unlike traditional SEMs, it collects EDS data continuously in the background. Unique algorithms process SEM and EDS signals simultaneously, so you can view the morphology and quantitative elemental composition of a sample together, in real time.

For quantitative elemental information at any time

Designed to make SEM easier to use

Compared to alternative SEM-EDS systems

Large, flexible chamber

How SEM/EDS is used in failure analysis of steel, with examples of bend test failures, coating defects and corrosion in the automotive industry.

SEM-EDS can be used to characterise the composition of polymer composites. This is useful in failure analysis, to detect and identify contaminants and defects, and to check homogeneity.

Combined SEM-EDS can be used to locate and identify contamination quickly and easily. The Thermo Scientific Axia ChemiSEM fully integrates the two techniques.

A case study of how SEM-EDS was used for failure analysis of thermal barrier coating in a turbojet engine, for materials development in aerospace engineering.

A recorded webinar from Thermo Scientific about how to match the features and specification of a SEM to the requirements of your application.