Benchtop Brake Material Screening System

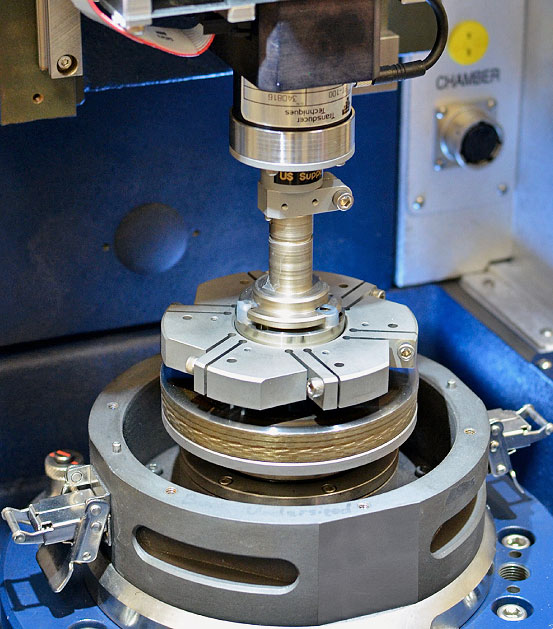

A new Brake Material Screening Module is now available for Bruker’s UMT Tribolab, for testing brake pad materials in the automotive industry. Save time and money by testing smaller samples on Bruker’s reliable, industry-tested, benchtop screening and characterisation platform.

Blue Scientific is the official distributor for Bruker tribology testing instruments in the Nordic region (Sweden, Finland, Iceland, Denmark, Norway). For more information and quotes, please get in touch:

Bruker UMT Tribolab

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Test Smaller Samples

The new module expands the capabilities of the Bruker UMT TriboLab, which is the most widely used platform worldwide for testing friction and wear. The test simulates the standard SAE J2522 (AK Master) test at benchtop scale for the first time.

Now you can test significantly smaller samples on a benchtop system. This shortens the total characterisation time from days to hours, speeding up brake material development considerably. There’s no longer any need to build whole brake pads for screening tests, when smaller samples can be tested quickly.

With faster screening you can quickly select the best sample materials to develop further for complete dynamometer functional testing. This will result in significant savings in costs and time, so you can get new products to market faster.

Test smaller brake pad and rotor material samples

Test Types

The new module measures friction under various conditions:

- Pressures

- Speeds

- Deceleration times

- Temperatures

The system applies comparable contact pressures levels to those used in a full-scale dynamometer rig. The UMT Tribolab is extremely flexible; you can easily programme industry-standard dynamometer protocols and standards, while monitoring key parameters such as friction and temperature.

Perform a comprehensive range of screening tests:

- Constant deceleration test mode

- Constant velocity (drag) test mode

- Brake material COF as a function of:

- Velocity

- Temperature

- Contact pressure

- Effect of humidity on brake material behaviour

- Fade and recovery protocols

Application Note: Correlation Between Benchtop & Dynamometer Tests

Brake Material Screening Tester Datasheet

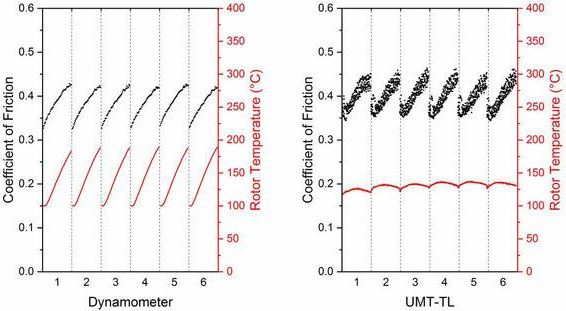

Results from the UMT Tribolab compared to a full scale dynamometer.

Bruker UMT TriboLab

The UMT TriboLab is the most versatile and widely used tribometer:

- Versatile, modular system

- Higher speeds, more torque and better force measurement than alternative instruments

- Perform all comon tribological tests at the nano and micro scale

Further Information

Blue Scientific is the official Nordic distributor of Bruker’s tribology testing systems. For more information or quotes, please get in touch:

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Bruker UMT Tribolab

UMT TriboLab Brake Material Screening Tester