Benchtop lubricant screening and materials qualification with a new HFRR module for Bruker’s tribometer.

Studying tribocorrosion with the Bruker UMT TriboLab tribometer, which combines tribology testing & electrochemical capabilities for measuring open circuit potential (OCP) during wear tests.

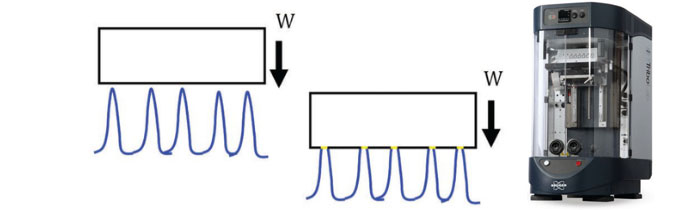

New module for testing brake pad materials in the automotive industry. Save time and money by testing smaller samples on a benchtop system, with the Bruker UMT Tribolab tribometer.

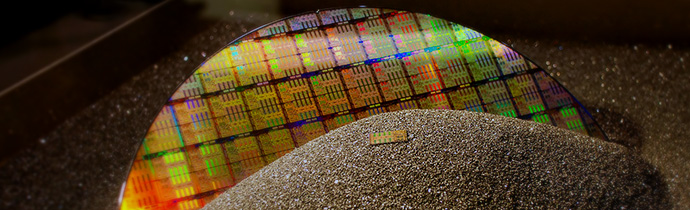

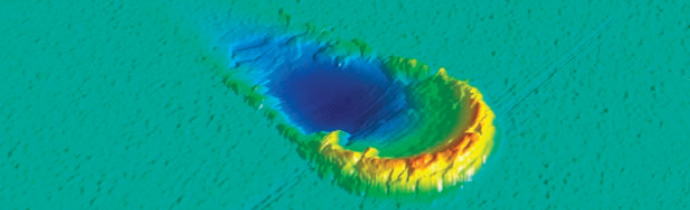

The Bruker TriboLab CMP is a new system for small-scale Chemical Mechanical Wafer Polishing in R&D. It reproduces full-scale wafer polishing process conditions with unique characterisation features. This is a new, updated system replacing the previous CP-4. Blue Scientific is the official Nordic distributor for Bruker Nano surface analysis instruments. For more information please get in […]

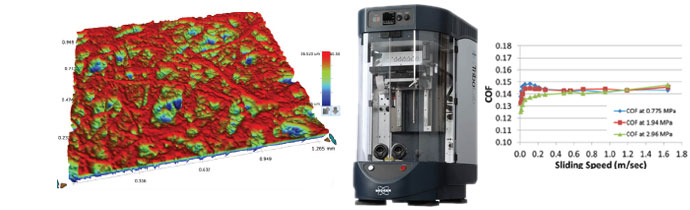

Using the Bruker UMT TriboLab in the automotive industry to test materials and simulate tests usually performed on a full-scale testing rig.

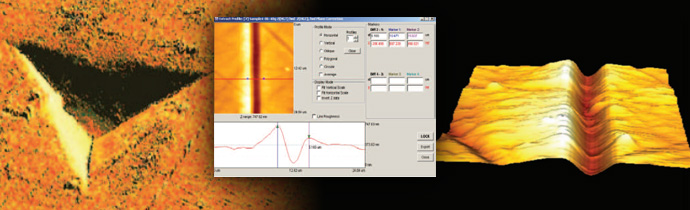

The amount of sliding friction between two surfaces is affected by a number of factors, one of the most obvious being surface texture. But how exactly does the roughness or smoothness of a surface affect its sliding friction? And what about different situations, such as elastic deformation? Donald K. Cohen PhD has published an interesting article […]

New nano-scratch option for the Bruker NanoForce nanomechanical testing system, for nanoscale scratch testing.

Testing Thin Films and Coatings with the Bruker UMT TriboLab Test the material properties of thin films and coatings with the Bruker UMT TriboLab. Perform a wide variety of mechanical tests on thin films and coatings including: Nano- and micro-indentation tests for coating nano/micro-hardness and elastic modulus evaluation Scratch-hardness tests under constant load for scratch resistance and […]