Analysing Thin Films and Coatings with X-Ray Reflectometry

X-ray Reflectometry (XRR) is a fast, non-destructive method for measuring the thickness, roughness and density of thin films, coatings, multi-layers and superlattices.

Blue Scientific is the official Nordic distributor for Bruker XRD in the Nordic region (Norway, Sweden, Denmark, Finland, Iceland). For more information or quotes, please get in touch.

XRD Instruments

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Follow @blue_scientificX-Ray Reflectometry

X-ray Reflectometry (XRR) is a fast, non-destructive method for measuring the thickness, roughness and density of:

- Thin films

- Coatings

- Multi-layers

- Superlattices

- Crystalline and amorphous films

Instrumentation

These examples use a Bruker D8 DISCOVER XRD system, equipped with an EIGER2 R 500K detector.

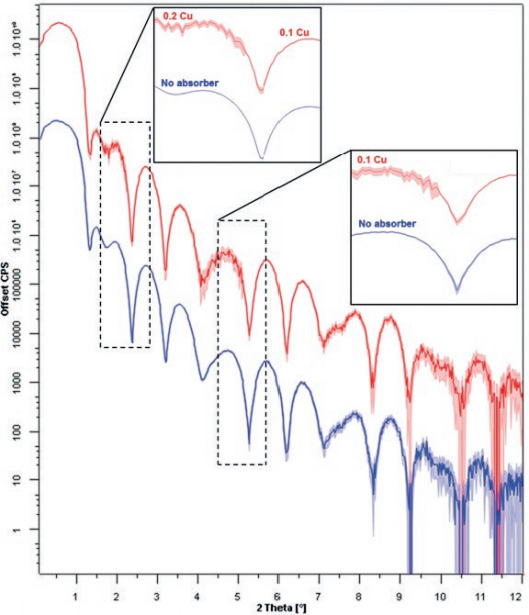

Typically, XRR data is acquired over several consecutive scans using absorbers of different thicknesses. With the Bruker EIGER2 R 500K detector, the entire scan can be obtained in a single range without absorbers, and intensities are collected from the full dynamic range. This results in much less statistical error:

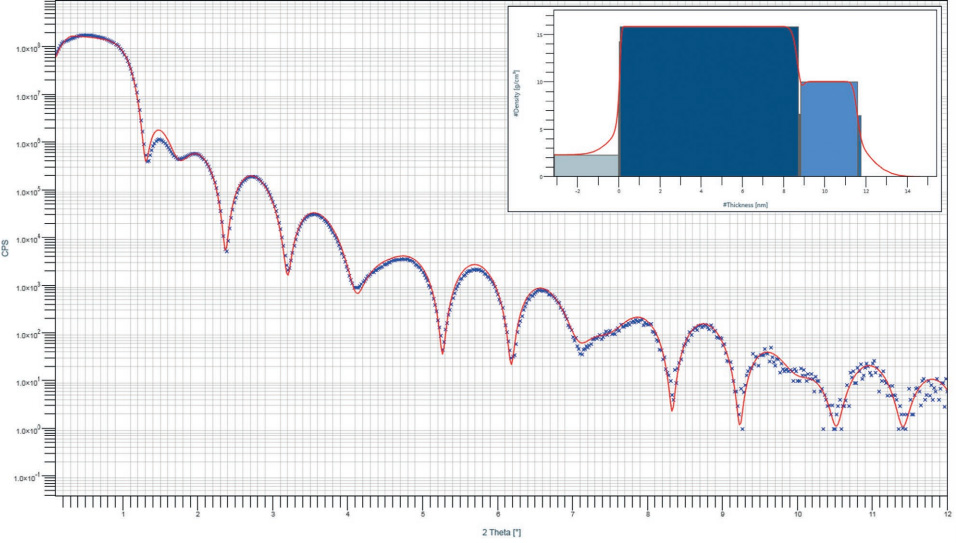

Example: Ta Coating on Si

In this example, a Ta coating on Si was measured with XRR. The scan took 10 minutes and revealed interfacial oxide and contamination layers.

The measurement identified native oxide layers SiO2 and Ta2O5, and a surface layer of amorphous C. An accurate fit was achieved by taking into account both the Ta film and oxide layers, and the asymmetric interfacial density profiles. The film thickness was measured as 8.7 nm, with a 2.8 nm Ta2O3 native oxide layer on top.

The surface carbon layer is probably the result of long term storage in atmosphere.

More details, including experiment parameters, are available in an application note from Bruker.

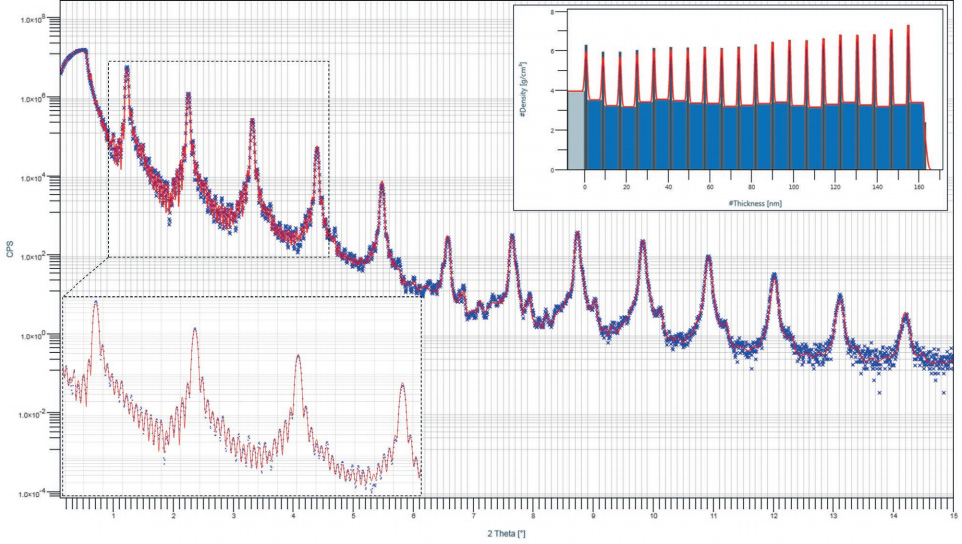

Example: GaN/AlN Superlattice

In this example a complex 20-layer GaN/AlN superlattice was scanned for 24 hours to resolve the fine structure.

The initial superlattice model was assumed to be uniform, with the same thickness, density and roughness. However, the quality of the fit was improved by a factor of 6 by expanding the superlattice and allowing the thickness, density and roughness of each layer to vary independently. This revealed subtle variations in the layers. The result is shown below, with the density depth profile in the inset.

- Density: The density of the GaN layers increases systematically from 6.0 to 7.3 g/cm3. The thicker AlN layers vary randomly between 3.2 and 3.6 g/cm3.

- Thickness: Relatively uniform, varying from 1.2 – 1.3 nm (GaN) and 6.8 to 6.9 nm (AlN).

- Roughness: Decreases systematically from the substrate to surface, from 0.4 nm – 0.3 nm (GaN) and 0.4 nm – 0.2 nm (AlN).

What does this tell us? The systematic change in density of the GaN layers, together with the change in roughness, suggests that the deposition conditions require tighter control, particularly for the GaN.

More details about these examples is available in an application note from Bruker, which includes experiment parameters.

EIGER2 XRD Detector

The Bruker EIGER2 is a powerful XRD detector that extends the capabilities of the D8 ADVANCE and D8 DISCOVER family of XRD systems:

- High frame rate for 2D data collection in continuous scanning mode

- Single photon counting without spatial distortion

- Highest count rates and dynamic range

- Switch between 0D, 1D and 2D mode

Further Information

Blue Scientific is the official distributor of Bruker XRD. We’re here to answer your questions and provide quotes – just get in touch: