Fast AFM with the Bruker Dimension FastScan

Fast AFM with the Bruker Dimension FastScan, without compromising resolution or image quality. This opens up applications for AFM, giving you a rich, nanoscale overview of your sample at the nanoscale in minutes rather than hours.

Further details are available in an application note from Bruker.

Blue Scientific is the official Nordic distributor for Bruker Nano Surface Analysis in the Nordic area (Norway, Sweden, Denmark, Finland, Iceland). For more information or quotes, please get in touch.

Bruker AFM

Contact us on +44 (0)1223 422 269 or info@blue-scientific.com

Follow @blue_scientificHigh Speed AFM

Compared to other nanoscale imaging techniques (eg optical microscopy, SEM and TEM), the usage of Atomic Force Microscopy has traditionally been limited by its slower imaging speed. To combat this problem, Bruker R&D focussed on speeding up the imaging process while maintaining the same high resolution – this lead to the development of the Dimension FastScan.

Faster imaging benefits all three main areas where AFM is used:

- Surveying – Looking at an unknown, heterogeneous sample for an overview of the surface morphology.

- Screening – Quantitative characterisation of the surface properties of a large number of samples eg roughness, phases, particle size and shape, stiffness, etc. The results for the sample set can then be plotted against parameters such as temperature, concentration or stress.

- Dynamics – Observing changes over time eg protein dynamics, aging phenomena, etc. Fast imaging is necessary for a useful frame rate.

Optimising AFM Technology

To accelerate the speed of AFM, Bruker R&D optimised each component of the microscope. Further detail about each is available in this application note.

- Cantilever – For the best combination of flexibility and sharpness

- Laser optics – Three spot sizes to suit each cantilever and probe

- Z scanner and driver – Increased resonance, while maintaining range, linearity and compatibility with fluids

- Electronics – For high speed with the required performance reserve

- XY scanner – Flat scanning motion at high speeds

- Vision optics – Automatic focussing prior to engagement and motorised positioning, controlled by the software

- Workflow – For maximum efficiency, guiding the user step-by-step

Tip Abrasion

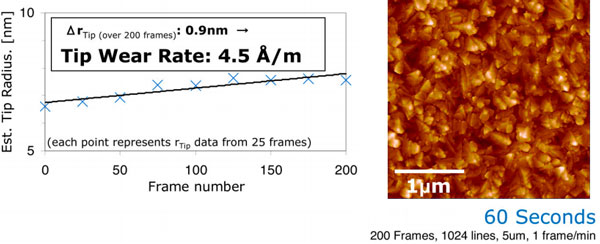

A common concern is that fast scanning affects tip life, with abrasion caused by covering a larger surface in a shorter time. This would affect your productivity and increase running costs. Tip life is also a measure of a system’s force control.

In the example below, a TipCheck sample from Aurora Nanodevices Inc. was measured with the Dimension FastScan. This is a test sample that’s used to measure tip sharpness, with lots of sharp edges. They’re often referred to as “tip-eaters” because of the excessive wear they cause.

The “tip-eater” was scanned at a fast rate of 17 lines per second. The estimated tip radius was plotted against the number of frames. This shows that fast imaging of a very rough, hard sample wears the tip radius very slowly: 0.9 nanometres over 200 frames. This is an extreme scenario, so this level of abrasion cannot be expected for most sample types. As well as demonstrating the upper limit of tip abrasion, this also highlights the FastScan’s low-force tracking performance.

An Overview of your Sample

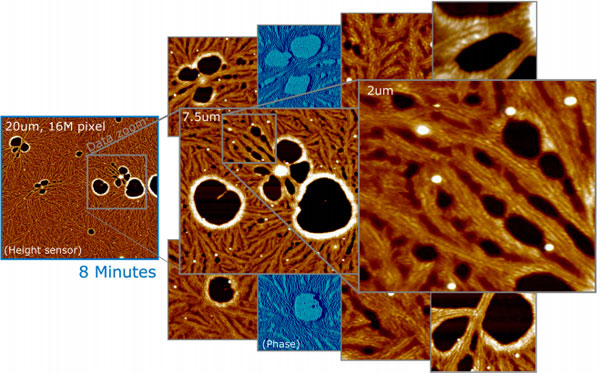

Surveying a new surface is one of the most common uses of AFM. It involves capturing an overview of the sample to understand what’s important, rather than looking at details or generating final images.

By scanning a large area at high resolution, you can then zoom into interesting areas, and even crop to create publication-quality images without additional scanning. You can decide on the best scale and framing after acquiring your data. With the Dimension FastScan you can capture a high resolution 16 megapixel image in minutes rather than hours, making this a realistic, practical option.

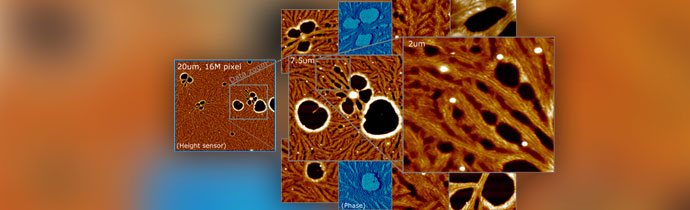

In the example below, a PTFE polymer film was scanned in only 8 minutes. The details are zoomed-in portions showing interesting morphology, together with phase data. An overview of the sample like this provides information about the types of morphology that can occur on the surface, as well as high quality images.

PTFE polymer film (20µm, 16Megapixels) with data zooms showing detail and phase data. Acquired in 8 minutes using the Bruker Dimension FastScan.

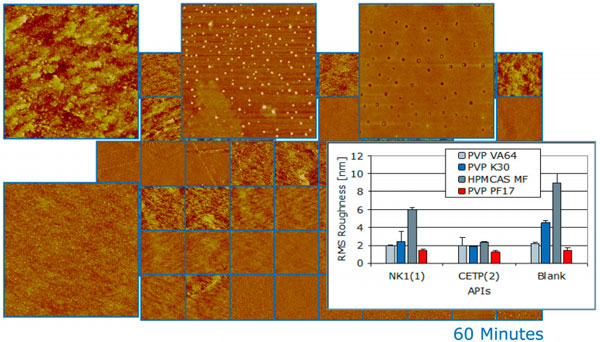

Screening Batches

Another common AFM application is screening large numbers of samples to understand the relationship between a certain parameter (eg ingredient concentration or process parameter) and a nanoscale morphology or property (eg roughness, number of phases, domain size, defect rate or mechanical property).

This involved scanning multiple areas on a series of samples. Speed is necessary for high throughput. Other ways to increase efficiency include the ability to load multiple samples, automation, fast engagement and batch image analysis.

In the example below, samples were screened for pharmaceutical product development. The active pharmaceutical ingredient (API) was combined with an excipient to form an amorphous solid, to aid solubility after ingestion. The amorphous formulation is solid at room temperature but would otherwise phase separate. To observe the phase separation with bulk techniques, relatively macroscopic (~100nm) separation and re-crystallisation of the API must first occur.

With the Dimension FastScan, you can find indicators of instability on a much smaller scale, much earlier. In the pharmaceutical industry, data is required from 100 or more samples each day – taking advantage of >10x faster scan speeds, fast engagement, multiple sample automationand robust measurements together with high data quality.

Dynamic Processes

The third main area for fast AFM is the time-resolved study of dynamic processes on the scale of proteins and DNA. As well as speed, it’s also important that tip-sample forces are non-destructive.

By increasing imaging bandwidth and balancing image quality with speed,

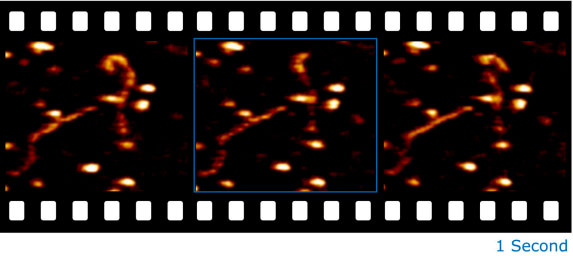

frame rates >1 frame per second can be achieved. While individual frames might not appear as high quality, in a movie this is acceptable.

The example below shows three frames from a sequence of 2100, captured at 1 frame per second, of DNA in buffer solution, loosely bound to and diffusing on an APS-treated mica substrate. The movie shows the movement of the DNA, including a sliding motion that shows the DNA’s binding to the substrate is loose enough to allow movement. Diffusion is not dominated by the AFM tip’s back-and-forth scan motion. This is a foundation for studying more complex sample systems, eg DNA-protein complexes, ATP-driven systems, etc.

Bruker Dimension FastScan

- Fast imaging without compromising resolution

- Complete range of AFM modes

- Quantitative nanoscale property mapping

- Suitable for a wide range of sample types, from soft biological samples to very hard materials

Further Information

Blue Scientific is the official Nordic distributor of Bruker AFM. We’re available to provide quotes, demonstrations and answer all your questions – just get in touch: