Add Nanomechanical Testing to your SEM

Add nanomechanical testing capability to your SEM (Scanning Electron Microscopy) with the new Hysitron PI 87xR SEM PicoIndenter. Enhance the capabilities of your tribology or nanoindentation lab with the new depth-sensing nanomechanical testing for SEM attachment.

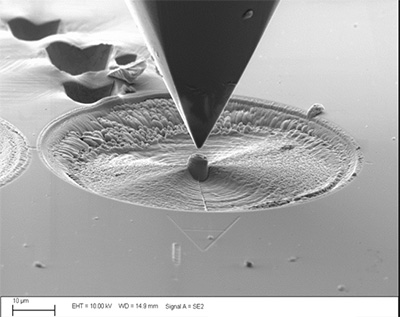

Hysitron’s PI Series SEM PicoIndenter® is a depth-sensing mechanical test system that interfaces with scanning electron microscopes. Perform quantitative nanomechanical testing while simultaneously imaging with your SEM. Coupling these two techniques enables you to position the probe extremely accurately, as well as imaging the deformation process throughout the test.

Hysitron’s PI Series SEM PicoIndenter® is a depth-sensing mechanical test system that interfaces with scanning electron microscopes. Perform quantitative nanomechanical testing while simultaneously imaging with your SEM. Coupling these two techniques enables you to position the probe extremely accurately, as well as imaging the deformation process throughout the test.

You can test samples including metals, alloys, ceramics, composites, polymers and biomaterials.

For more information, contact us on 01223 422 269 or info@blue-scientific.com

View our range of scientific instruments

A key feature of the PicoIndenter is the facility to watch the indentation as a video. The Hysitron PI 87xR SEM PicoIndenter is the most advanced in situ mechanical testing instrument available, from micro- to nano-scale.

- Heavier load capacity up to 100mN

- New heated tip and stage option – up to 800º

- Watch the indent as a video! See the loading curve of a nanoparticle crack under load.

Watch a video of the indent!

See the nanoparticle as it cracks under load.

Benefits

- Test a wide range of samples, with a high maximum load of >100 mN and displacements up to 150 µm.

- Industry-leading noise floor, bridging the gap between nano- and micro-scale.

- Increased normal force range for large and/or hard structures that require larger loads to induce failure, fracture or yield.

- Test compliant samples eg polymers, organic materials.

- Indentation probe options for a range of geometries, suitable for most high force/high displacement tests.

- Compatible with most SEMs.

Applications

Quantitative measurement of nanomechanical properties including:

Quantitative measurement of nanomechanical properties including:

– Hardness

– Stiffness

– Modulus- Fracture onset characterisation

- Crack propagation

- Delamination

- Pile-up

Options include: up to 800 degree heating, electrical characterisation and PTP (push-to-pull) tensile and DMA dynamical characterisation.

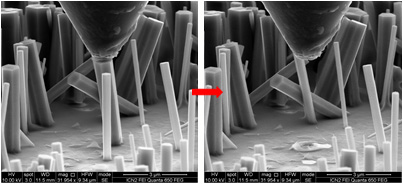

In-situ pillar compression. Piezoelectric ZnO nanowires grown by hydrothermal process. Courtesy: Dr. Gonzalo Murillo del IMB-CNM (CSIC) Spain

Contact us for more info: 01223 422 269 or info@blue-scientific.com

View our range of scientific instruments

Techniques

NANOINDENTATION

Control and measure force and displacement precisely. Quantitative measurement of fundamental mechanical properties such as hardness, elastic modulus and creep performance. Directly observe the deformation, with data-video correlation.

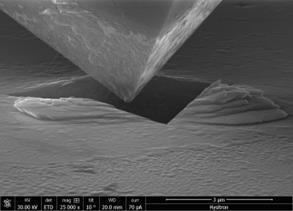

COMPRESSION

Precise tip placement using electron microscope imaging, for verification of tip-sample alignment while compressing pillars and particles. High-speed video capture verifies the extent of the compression, onset of yield and reveals unique deformation mechanisms in small-scale samples.

TENSILE

Direct-pull and push-to-pull (PTP) testing of dog-bone specimens, thin films and nanowires. Measure tensile properties in situ and observe stress-strain behaviour in advanced materials not easily tested using traditional means.

BEND

Accurate loading alignment and specimen measurement using electron microscope imaging. Straightforward stiffness and fracture toughness measurement of single-phase, composite and multi-layered materials.