XRM for Pharmaceuticals and Medical Devices (X-Ray Microscopy / Micro-CT)

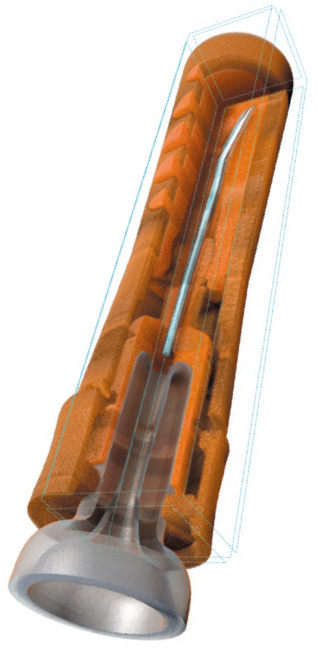

XRM (X-Ray Microscopy / Micro-CT) is used around the world for inspection of pharmaceuticals and medical devices. Here’s an overview of the benefits of the technique and how XRM is used for a variety of applications, from API distribution and tablet coating analysis to inspection of complex devices such as inhalers and implants.

XRM for Pharma and Medical Devices

Bruker’s new video provides a quick introduction to X-ray microscopy (2 min 22):

Non-Destructive Testing

XRM (also known as micro-CT) is a powerful technique for 3D internal imaging with sub-micron resolution. It’s non-destructive and requires little to no sample preparation, so there’s no laborious thin slicing, coating or embedding. This makes it a convenient, useful method for examining the inside of objects.

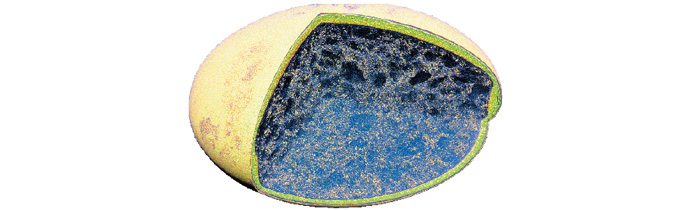

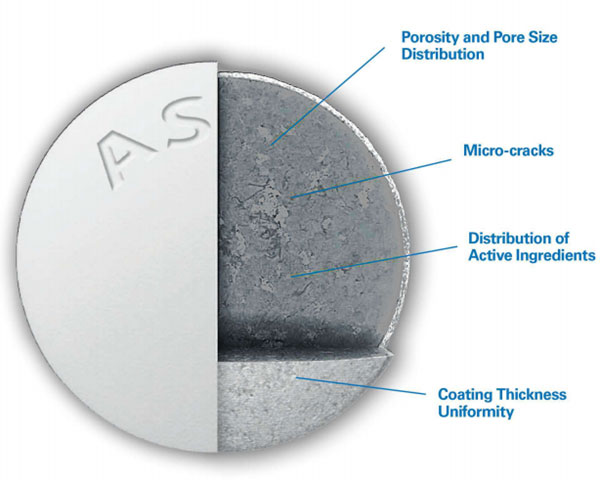

Tablets

Gain immediate insights into the internal structure of tablets, to accelerate product development.

- Tablet compaction density – Percentage porosity, pore size and distribution.

- Micro-cracks – Locate stress-induced micro-cracks in tablets and layered products.

- Active ingredient distribution – Calculate the total volume and percentage volume.

- In-situ compression testing – Dynamic testing of mechanical properties.

- Coating thickness – Measure thickness and uniformity.

This information can then be used to optimise production factors such as compressive force, vacuum strength and mixing ratios.

More examples of micro-CT in pharmaceuticals…

Packaging

Examine packaging and seal integrity for all kinds of drugs and pharmaceutical products including vials and injections. This can help identify non-conforming packaging machines, expose variation in components and highlight problematic design issues.

- Seal integrity – Locate gaps and leakages.

- Process optimisation – Compare variations in sealing and closure processes.

- Component variation – Measure the dimensional variation of components.

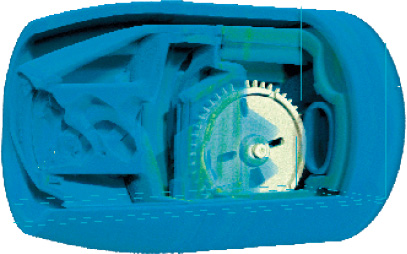

Product Inspection

Examine the inside of objects without cutting them. Testing is fast and non-destructive, so packaging assembly can be checked, to ensure successful production.

- Check alignment – Visualise internal components without opening the packaging.

- Measurements – Quantitative measurements in 3D.

- Performance evaluation – Pre- and post-usage, without affecting product performance.

Failure Analysis

Identify the root cause of failures without damaging the sample, with virtual cuts and even flights through objects. It’s then possible to use further analytical techniques on the same sample for a comprehensive investigation.

- Non-destructive investigation – Examine where and how the failure happened.

- Root cause analysis – Compare perfect and imperfect products.

- Digital archiving – Save 3D reconstructions for future reference.

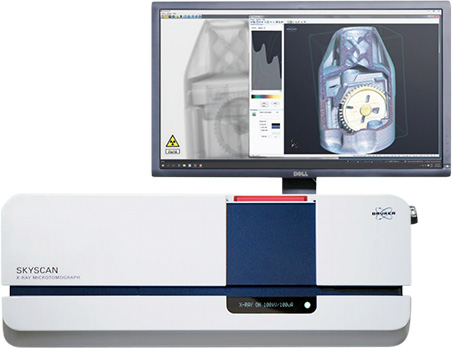

Bruker SkyScan 1275

- Automated, self-optimising XRM system.

- Fast scanning in as little as 80 seconds, and the world’s fastest image reconstruction.

- Small footprint, benchtop instrument.

- No special infrastructure requirements; needs only a standard power outlet.

Recorded Live Stream

In Bruker’s Live from the Lab session, XRM specialists discuss non-destructive inspection, with demonstrations from Bruker’s applications lab. A recording of the 30 minute session is available to watch on YouTube:

Download a Brochure

Bruker’s brochure explains the key areas where XRM is used in the pharmaceutical and medical device industry.

More Information

Blue Scientific is the official distributor of Bruker SkyScan XRM systems in the UK and Nordic region. We’re available to answer all your questions and advise on which system would best suit your work – just get in touch: